Dear all Unfortunately I had an accident last week. Very strong (and unusual) gust of wind tipped over my Vixen SXP2 mount. It fell exactly on the side, broke all plastic covers for knobs and scratched one side. Luckily I didn't have telescope on it. I was hopeful nothing too bad happened, but of course I can see problems: - When I move scope manually in RA and DEC I can feel small 'click' somewhere in the middle going to both directions

- When I polar align (I have screenshots of PHD2 polar alignment) for example on the West side and when I move it to East side it seems that telescope is out of polar alignment, I aligned it again on the East side

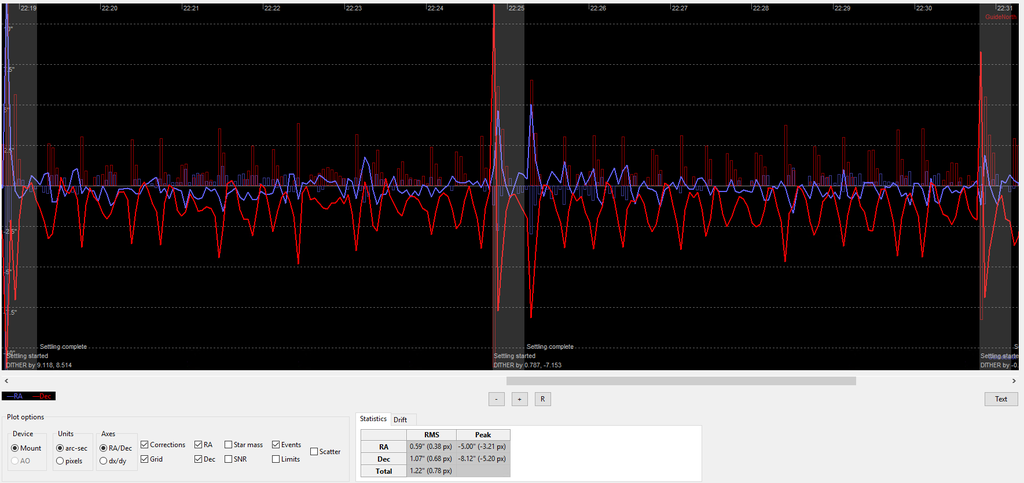

- Once it was PA on East side I slew to east target (Horsehead) and initially guiding was working well but over the time it starts to degrading a lot (having big jumps of 1", 2" always in one direction which was corrected by PHD2)

- After meridian flip again it seems like mount wasn't PA so I PA it again (again with PHD2) and slewed to target - it was working again a little bit better initially (0.6"-0.7" which is quite bad for this mount, usually I was in range 0.4"-0.5") and degraded over time again

- On one occasion also the movement (very regular position towards west) was very weird - like the mount couldn't move anymore. After that I re-aligned it to west horizon, restarted the mount and then it could move without any problems again.

So my conclusion is that mount was damaged and it's really hard to use it now. Even if I somehow calibrate it is working sub-optimal. I would like to ask forum for any feedback. Has something similar happened to any of you? Does anybody have experience with reparinig/servicing Vixen in Europe (Switzerland importer forwarded me to Bresser Germany for this). Did anybody try to open and fix mount on its own? I asked once Vixen for any instructions how to open & maintain SXP2, but they weren't very helpful. I also couldn't find any instructions online. I am thinking to open it and just try to look if I see something obvious. Thanks for any feedback! Regards, Jure

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

It did happen but no damage at all, scope or mount, thanks to the table nearby. I did several repairs in the past , complete overhauls and such and I'm confident that if anything that needs replacing can be replaced, signally the bearings, then restoring the mount can be done. If, however, there is damage to worm/worm wheel it is going to be exceedingly difficult to replace them as Vixen will never ever give them out as spares.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I did own Sphinx DX. I did alot of adjustments on the worm/gear spacing to reduce backlash, but nothing more. I completely disassembled a GPDX, re-grease and reassemble. The GPDX had no bearings, only bushings. These mounts are pretty simple. If you disassembled, take a photo of each step. It is easy to forget where a washer goes, are on which axis. The Ra/Dec shafts can be aluminum or steel. The GPDX are steel. It would take a lot of force to bend them. However, the screws holding the two axis together might become damaged.

I did drop my Mach1 on a concrete floor. I stupidity forgot to remove the counter weights, while removing the bolts holding the mount to the tripod. My leg stopped some of the impact force and I still have the scar. The contact was on the saddle clamp bolts. Bent both of them. I put the mount back on the tripod and it has ran every sense as if nothing happened. A new saddle was added.

Lynn K.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Since it's already damaged you really have nothing to loose by taking it apart and seeing if you can find the problem.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Thanks for all the responses. I agree, I started to disassemble it yesterday and I hope I can find a fault. For now everything seems in order. I also need to find a grease to clean it up and regrease it. As I want to do it quickly and don't have time to wait internet shipment, I think I will go with Baader Machine Grease #4 that I can buy locally in the store. I would be happy to get any more feedback especially about (dis)assembly of mount and re-greasing. This is my first time  |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

If the mount isn't decades old there is no need to re-grease and if anything a common weather-proof lithium grease will do. As said before, go slowly and take picture for each step and bag and label parts meticulously. There will bearings, both in tandem and single combos. Check that each one is properly seated and runs smoothly. This applied to both worm bearings as well as the axle bearings. There is no reason to think you'll nead bearing extractors but in case come back for advice. The most critical bit will be looking for obvious sign of damage to the RA worm/worm-wheel. Consider swapping wheels if the RA one is damaged (assuming they have the same ID, the number of teeth is just the same.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

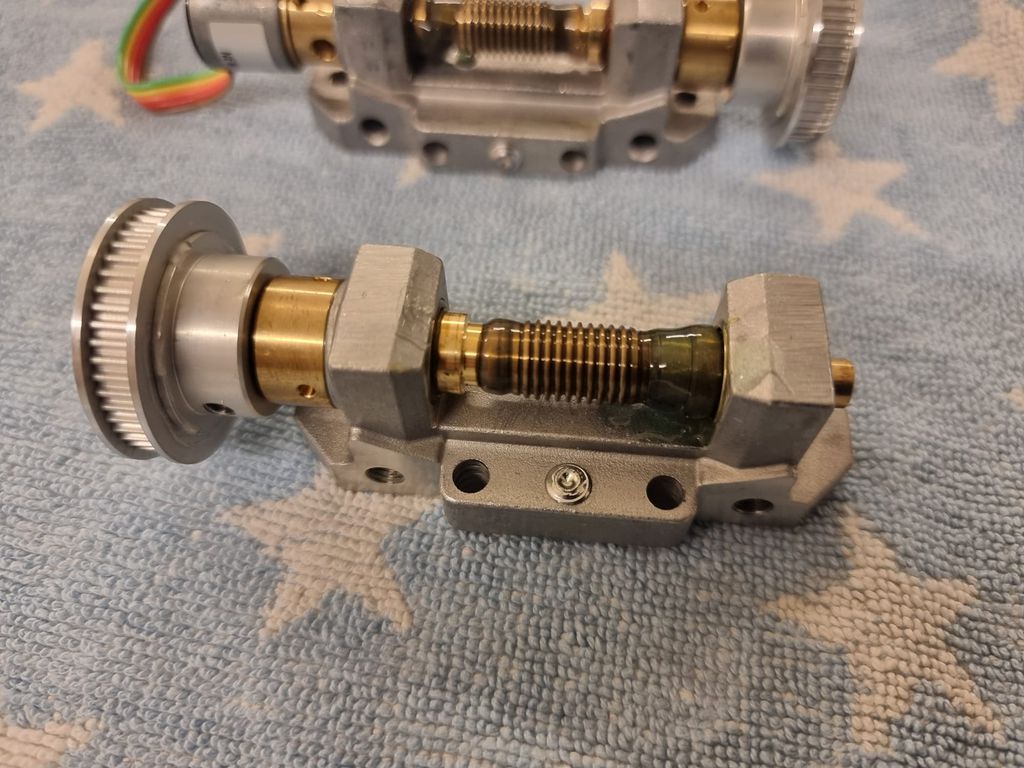

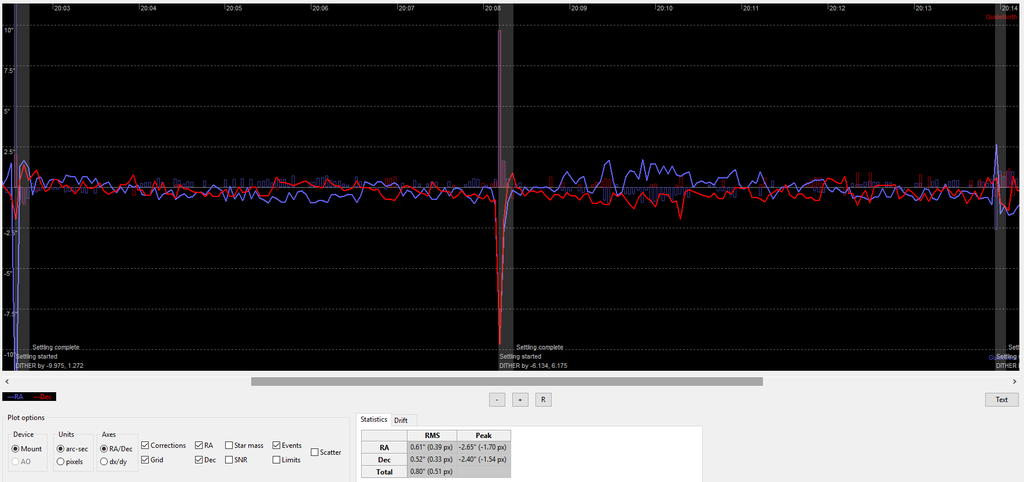

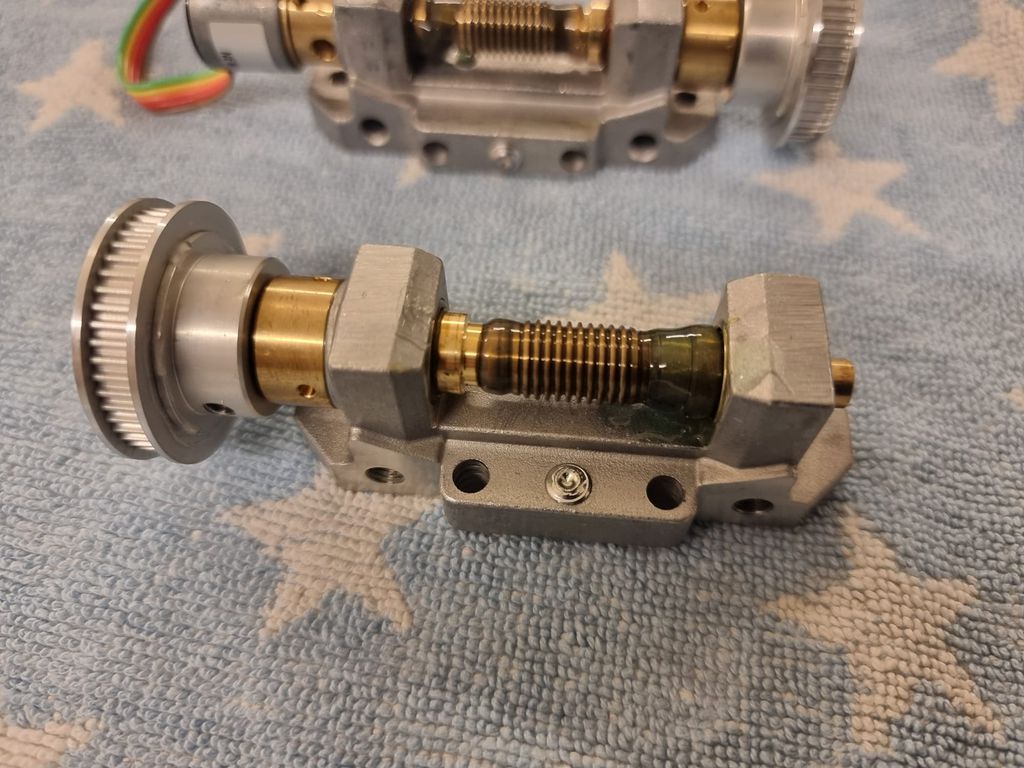

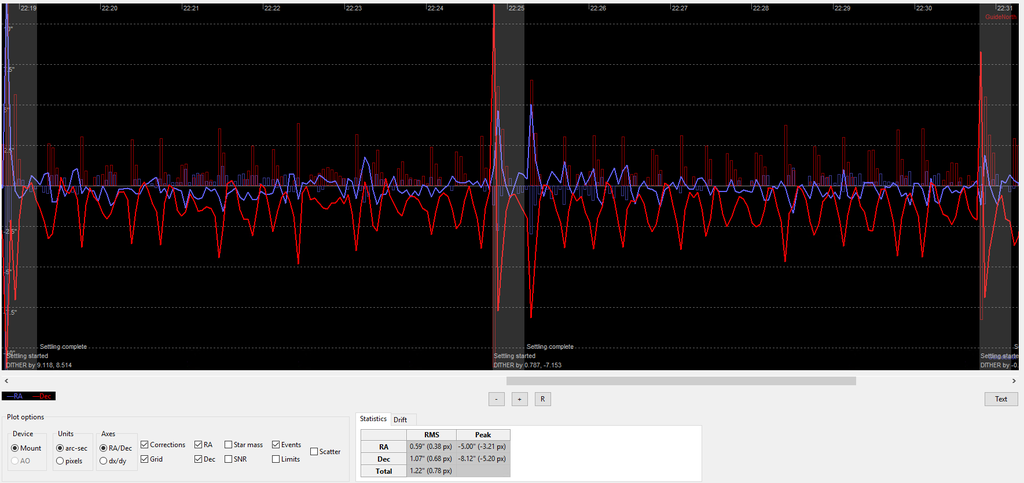

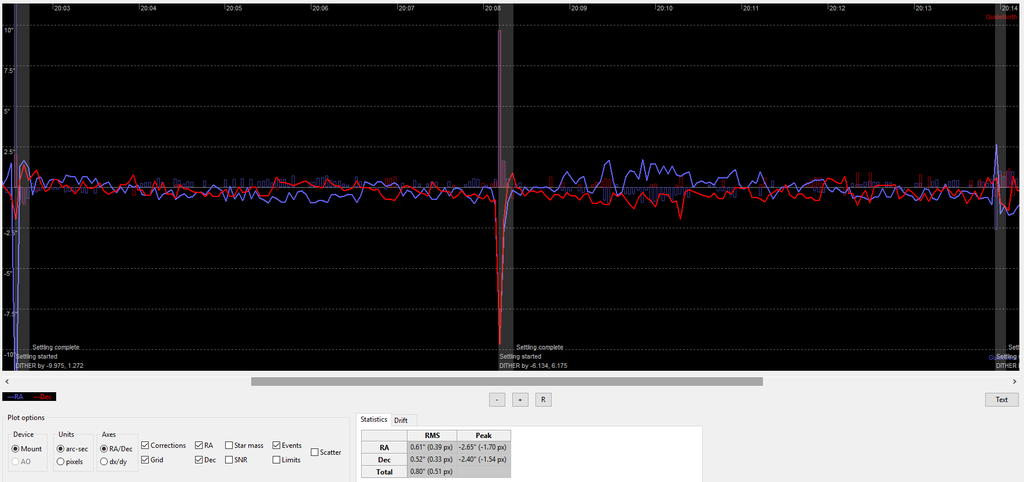

Hi Andrea Thanks for your inputs! I will not re-grease then as the worm/worm-wheels seems nicely greased. I don't notice any physical dents in the worm gears for RA or DEC. I did notice that DEC worm is not rotating smoothly. When I try to rotate it I feel 'clicks' (not sure if 'click' is right word but when I rotate it goes smoothly and at one point it just stops and needs more force to get out of this, it's one really obvious region and 1 or 2 smaller ones with this behavior):  I think this would explain why I've seen strong spikes in DEC in PHD2:  What I don't understand is why it changed from initial 'fair' guiding (worse than normal though) or why it changed completely when east to west flip happened (to me it seems like something would be loose and change position - similar effect as mirror flip on SCTs for example). This is initial guiding ~2 hours before the above guiding picture (these are two extremes - immediately after PA and at the end before meridian flip, but I notice similar but smaller jumps already after 1 hour):  One can see that even though RA is quite bad in guiding, at least is consistent over this hour period, while DEC changes completely. I will try to disassemble this DEC worm and see where this behavior is coming from. Thanks again for your input Andrea!

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

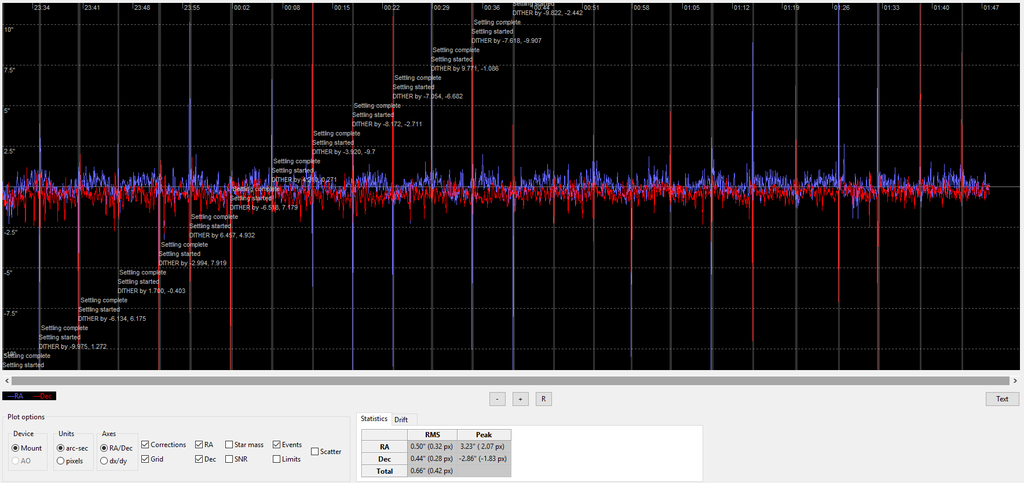

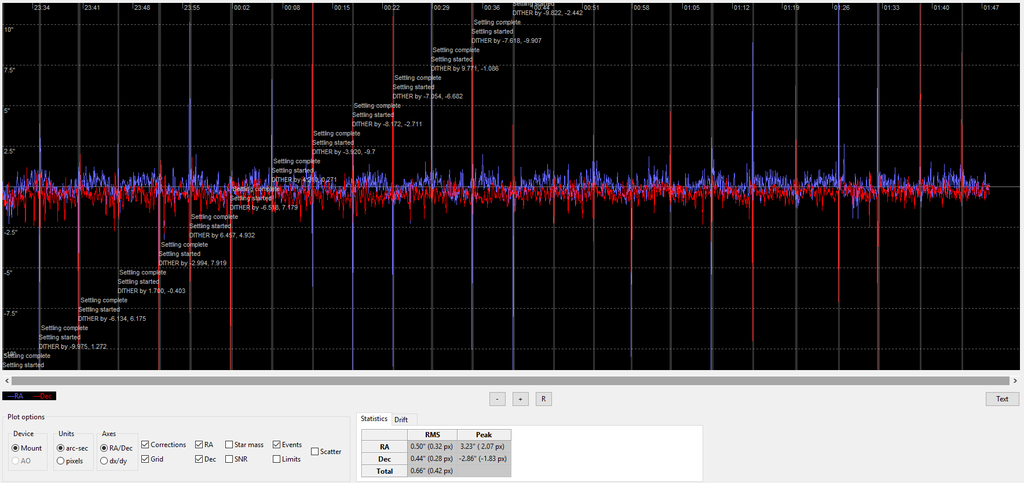

Interestingly enough, I am adding also the post meridian flip + additional polar alignment PHD2 graph (setup pointing west). It is more than 2 hours of guiding with 0.66" RMS which is not too bad. Just to remind: Initially I did PA on west but when I moved to east the PA was 'lost' ('bad'). I needed to do it again on east. After meridian flip (moving west) it was bad again and after new PA it seems the setup was working OK for > 2 hours. Interestingly enough in this direction the DEC doesn't degrade over time but keep the same behavior for these >2 hours of operation. Again maybe the DEC gear was in 'good position' not hitting the rough parts of the wheels?  |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Replace both worms bearings, that is the 4 of them. They do not usually cost much and better be safe than sorry. Get the best quality bearing you can get (they have different classes which correlate to smoother operation). The flip in behaviour of the Dec correction is due to different dirrection of correction once you flip the mount past the meridian.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I am having a little bit of issue to disassemble the worm gears to get to the gearings. I don't want to do it too much with force not to break anything. I did send e-mails to Vixen Japan and Bresser Germany (importer for EU and providing services for Vixen) if they have this spare parts. Let's see what is the answer (I guess you Andrea already know the answer, let's see if it will be officially confirmed  )

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I'm not holding my breath but you never know until you try…

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Update from my side (unfortunately not yet with results): - I found local precision mechanic shop & they changed the bearings in both worm gears, they needed only ~4 hours so it was really quick

- They used SKF W 618/6 bearings which seems like a good one

- Unfortunately the weather forecast is bad for the following few days (hopefully few stars for the weekend)

- The guy also gave me grease for gears and I bought one, I could get locally, but now I am not sure which one to use (any feedback appreciated):

- Vixen said they have spare parts but they don't ship them, they say I should ship the mount to Japan for them to fix it

- I have to say that Besser Germany (importer for Europe) was really helpful and try to push them to still send the spare parts, I am still waiting for response from them

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Standard lithium grease will do (or any machine grease, really), not that Baader obscene non-sense of 45 euro for a small can of grease. What's that, caviar?

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.