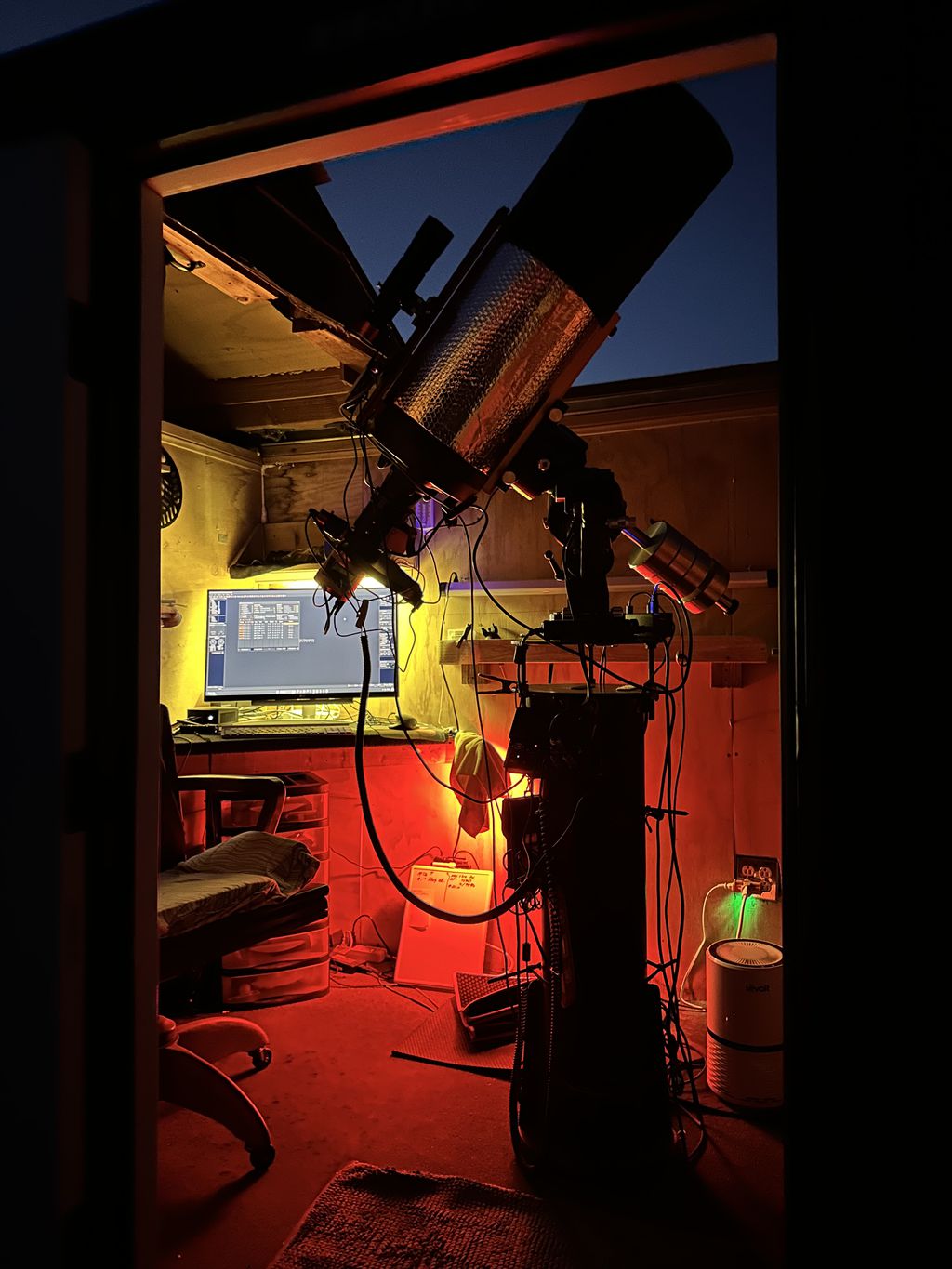

John at OOUK made me a CT8 with no finder scope holes and no rings. With that in hand Rouz and I went to work. We designed a 5-ring system and Rouz did what he does best and I couldn't be more pleased with the results. My goal was to maximize optical train stability. The 1st ring transfers stability from the forward metal OTA ring. The 5th ring transfers it's stability from the rear metal plate. Rings 1 and 2 sandwich the focuser mount plate to add stability to the imaging train. The top carbon fiber plate and the lower full length losmandy form a cage to lock in the rings and provide a stabilized cage system. I used carbon fiber rings from Rouz Astro for the finder also for light weight stability, no puny 3 point rings allowed. This finder is stable to compliment its host scope. I must repeat I couldn't be more pleased with how the project turned out. With state of the art technology such as this we all should be using carbon fiber rings from Rouz Astro. Carbon fiber is both lightweight and exceedingly strong. This rig is both stabilized and light weight letting your motors work less and thus more accurately. Dale P Carriere  |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Is that for a fighting tank?

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Could double as one. it ain't gonna bend today or tomorrow. And it's light enough that my 87lb wife can pick it up. She did it.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

The point of using a CF tube is that it doesn't bend on its own otherwise there is no real point in having it (except for lower thermal expansion but it isn't a real selling point here as everyone has autofocusing these days), as the weight of an aluminium tube equivalent system is about the same. And from what I gather Ruiz is using carbon-fiber "infused" plastics which isn't really CF.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Yes, the carbon fibre filament for 3D printers, only has about 10% carbon in it, so it’s not really carbon fibre at all, it’s 90% plastic. I tried it once and in my observatory it can reach 40 degrees C in the summer, and it warped big time, I personally don’t think it’s a good idea for scope rings, unless they are 100% carbon fibre.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

CF has tremendous tensile strength along the long axis of the fibers, it has much less 90 degrees to that axis or if the fibers are broken. That works great for the tube because it's a proper layup but because the fibers in 3D printed plastic are tiny bits scattered in a plastic matrix it's not nearly as strong as a proper CF layup where the fibers are continuous and layed up in the direction of tensile loading. It is a bit stiffer than regular PLA but it's brittle. https://www.youtube.com/watch?v=-Qpb0UTywko |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I am not even sure that 3D printing filament that is supposed to be carbon fibre, actually has any fibres in, or it just would not print, so it’s essentially only 10% of carbon what ? exactly…🤔

I have used both that and PETG, and found the later to be much better all round.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

That's my experince as well, PETG is the way to go.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

AstroStew:

Yes, the carbon fibre filament for 3D printers, only has about 10% carbon in it, so it’s not really carbon fibre at all, it’s 90% plastic. I tried it once and in my observatory it can reach 40 degrees C in the summer, and it warped big time, I personally don’t think it’s a good idea for scope rings, unless they are 100% carbon fibre. There are so many types of materials, each with its own strengths and weakness. There is a bit more to it than stated above  Yes, there is the $20 basic stuff form Amazon and a $300 printer. You are right to not expect much from it. There are also engineering grade materials, some even used in aerospace at $600 a roll -even with a small carbon ratio, these can be stronger than some metals (weight for weight). Keep in mind - "100% carbon fiber" doesn't exist - Typical parts made with fibers/fabrics are 40 to 50% glue (epoxy). |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

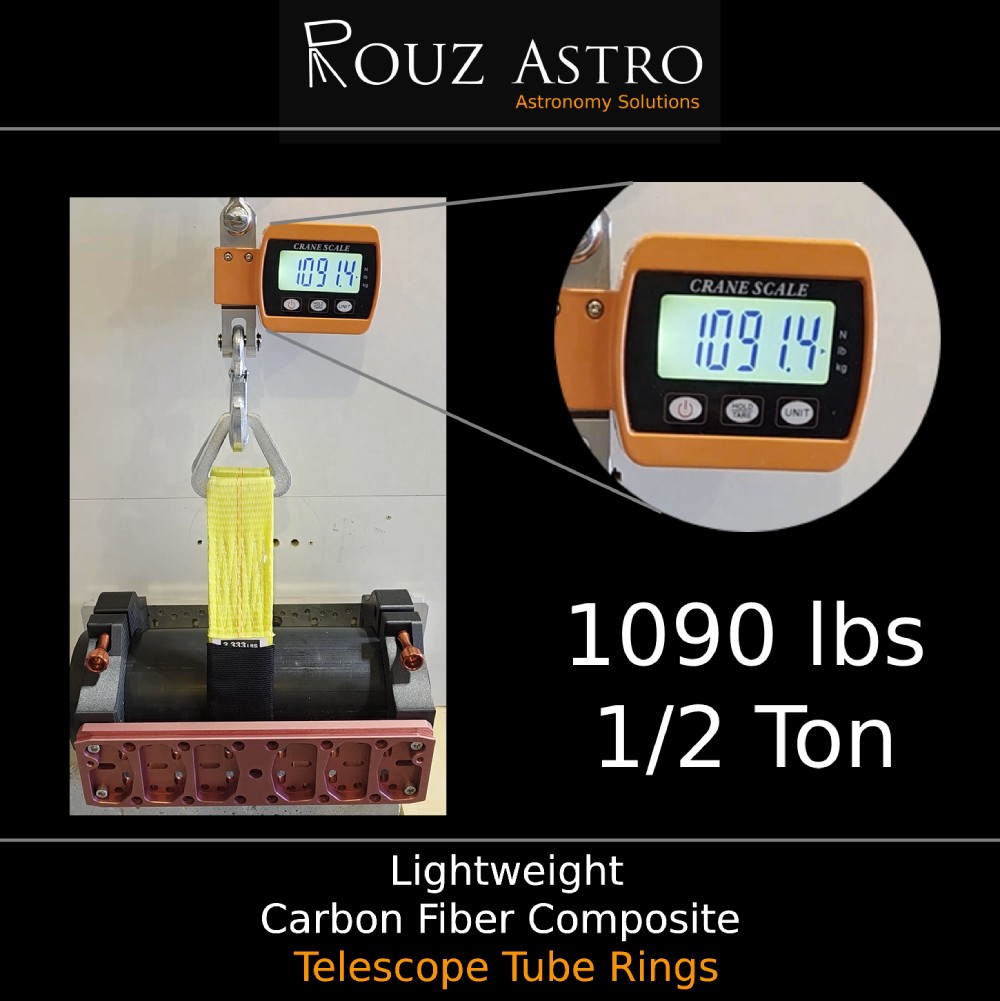

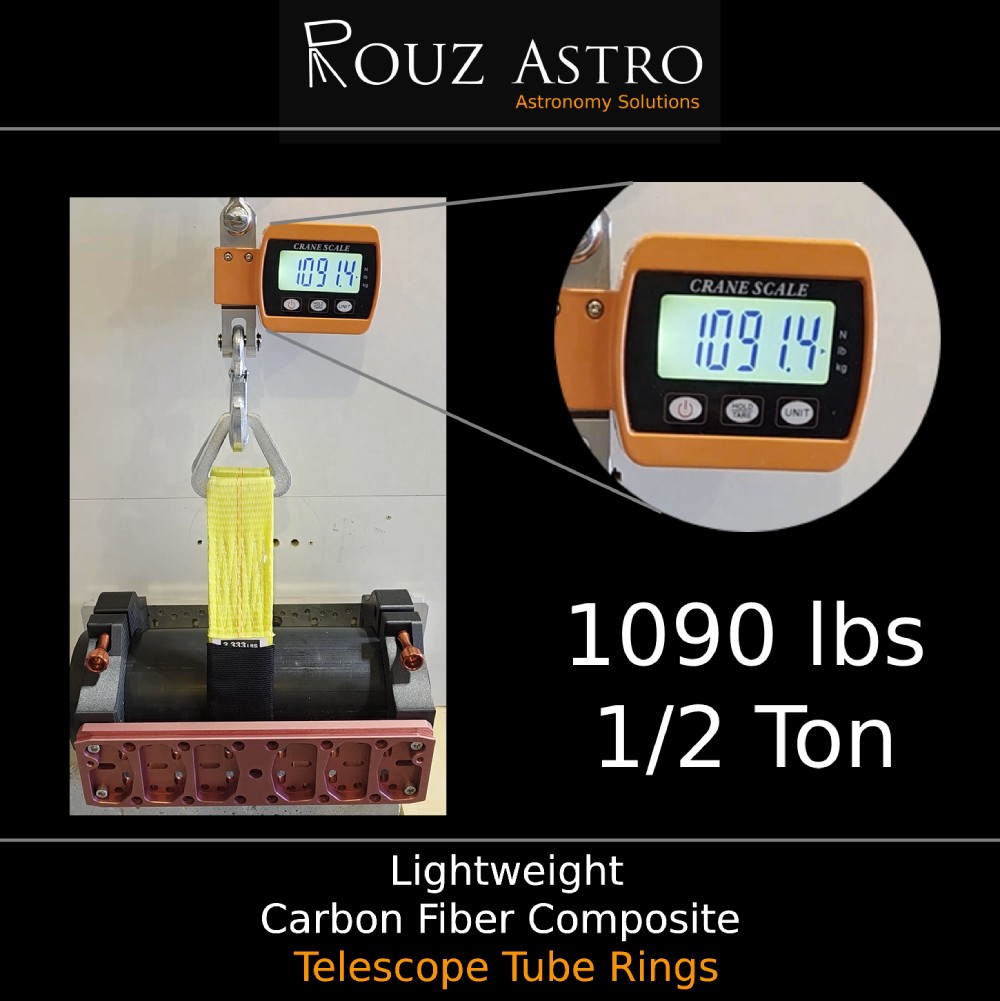

Here is a test of one off our smallest and lightest rings. We use engineering grade materials as well as design and manufacturing techniques that allows these parts to carry hundreds of pounds with ease: Video of a sample test: https://youtu.be/mv38p-yuD-c?si=zs1j5cG3Y6CRDl_x |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

andrea tasselli:

The point of using a CF tube is that it doesn't bend on its own otherwise there is no real point in having it (except for lower thermal expansion but it isn't a real selling point here as everyone has autofocusing these days), as the weight of an aluminium tube equivalent system is about the same. And from what I gather Ruiz is using carbon-fiber "infused" plastics which isn't really CF. Depends on the thickness. A basic 2mm thick carbon tube isn't all that stiff or strong. Yes, the advantage is the thermal expansion is much less - Also its easier to control internal tube currents compared to a fast cooling thin metal tube. Honeycomb sandwiching is where the magic happens. With carbon fiber tubes, if you get them thick with a light core, the strength and stiffness goes up exponentially. We also use similar techniques with our parts. The advantage being we can make complex shapes that are not easily possible with fabric layups. The majority of the cost of traditional carbon fiber parts is the labor and not so much the material itself. Standard modulus carbon fiber fabric: $25 to $50 per pound5.7 oz/yard² 2x2 twill weave, standard modulus dry carbon fiber: ~$30–$40/lb when purchased in rolls.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Rouz Astro:

AstroStew:

Yes, the carbon fibre filament for 3D printers, only has about 10% carbon in it, so it’s not really carbon fibre at all, it’s 90% plastic. I tried it once and in my observatory it can reach 40 degrees C in the summer, and it warped big time, I personally don’t think it’s a good idea for scope rings, unless they are 100% carbon fibre.

There are so many types of materials, each with its own strengths and weakness. There is a bit more to it than stated above

Yes, there is the $20 basic stuff form Amazon and a $300 printer. You are right to not expect much from it.

There are also engineering grade materials, some even used in aerospace at $600 a roll -even with a small carbon ratio, these can be stronger than some metals (weight for weight).

Keep in mind - "100% carbon fiber" doesn't exist - Typical parts made with fibers/fabrics are 40 to 50% glue (epoxy). You really can't compare carbon or mixed glass fiber or Kevlar resin layups with 3D printed "carbon fiber", these are totally different animals. $300 dollar printer or $2000 printer it's still FWM 3D printing with all it's pluses and minuses. The 3D printed "carbon" parts are no where near the same class a laid up, autoclaved, properly engineered CF part.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

My friend Rouz did not expound on this point, I will interject. It greatly depends on the carbon fiber modulus of the materials you are referring to. To which are you basing your arguments? Be it Amazon or industrial/research grade. Perhaps research on the mechanical properties of 3D printed carbon fiber composites would be a valid starting point for self education. After all Astrobin is all about educating and assisting one another.

Dale

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

AstroStew:

Yes, the carbon fibre filament for 3D printers, only has about 10% carbon in it, so it’s not really carbon fibre at all, it’s 90% plastic. I tried it once and in my observatory it can reach 40 degrees C in the summer, and it warped big time, I personally don’t think it’s a good idea for scope rings, unless they are 100% carbon fibre. As others have said, it depends on the base material. Some like High Temp Carbon Fiber Nylon (PAHT-CF) do quite well at higher temps. They also need a printer that can work with them, of course......

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

On a related note, I just saw that Polymaker has come out with a high temp PLA. Polymaker PLA High Temp |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Good input Bill. Polymaker should answer all the above unanswered questions.

Now let us move on.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Good input Bill. Polymaker should answer all the above unanswered questions.

Now let us move on. 😂😂 what unanswered questions ?

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I must say, that is a very well done setup. Very clean and neat!

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I must say, that is a very well done setup. Very clean and neat! Thanks JayBac. I try to keep cable runs as short as I can as that can lead to poor signal return. Dale

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Here's a short clip with another test of the rings: That should be enough strength for the average telescope! Each ring is made of 35 individual parts. After countless iterations an simulations, we are very happy with the current design. YouTube Link: https://youtube.com/shorts/wTsIifWYCy4?si=MVPjQdOntBixRfBT

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.