Hi Nick,

The rubber detritus is evidence that the pulleys are misaligned and the belt is rubbing against the block. The inner flange on the motor pulley should prevent this, but isn't, which means it isn't far enough out on the motor shaft , (or the motor mounting surface is too far in).

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

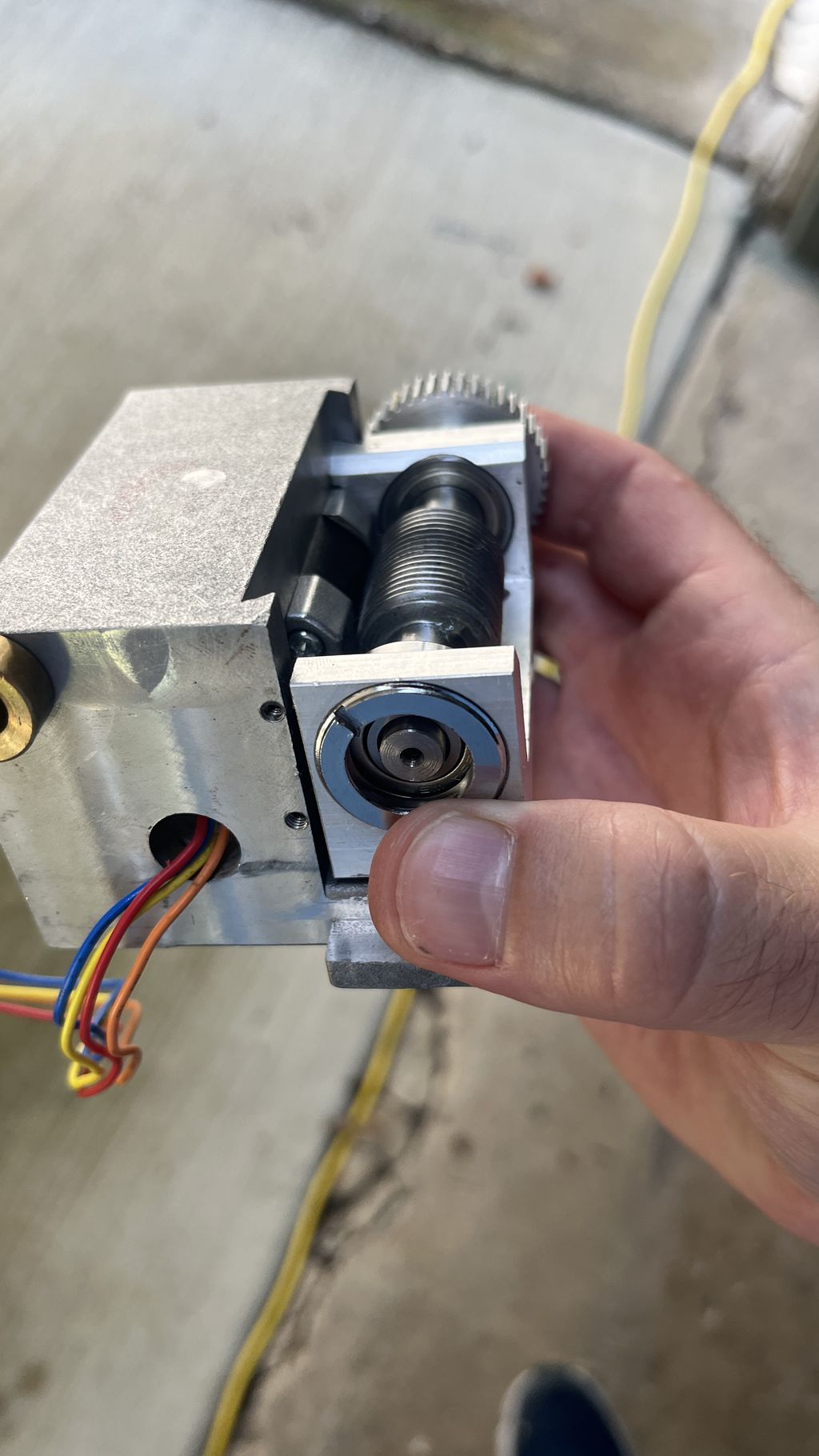

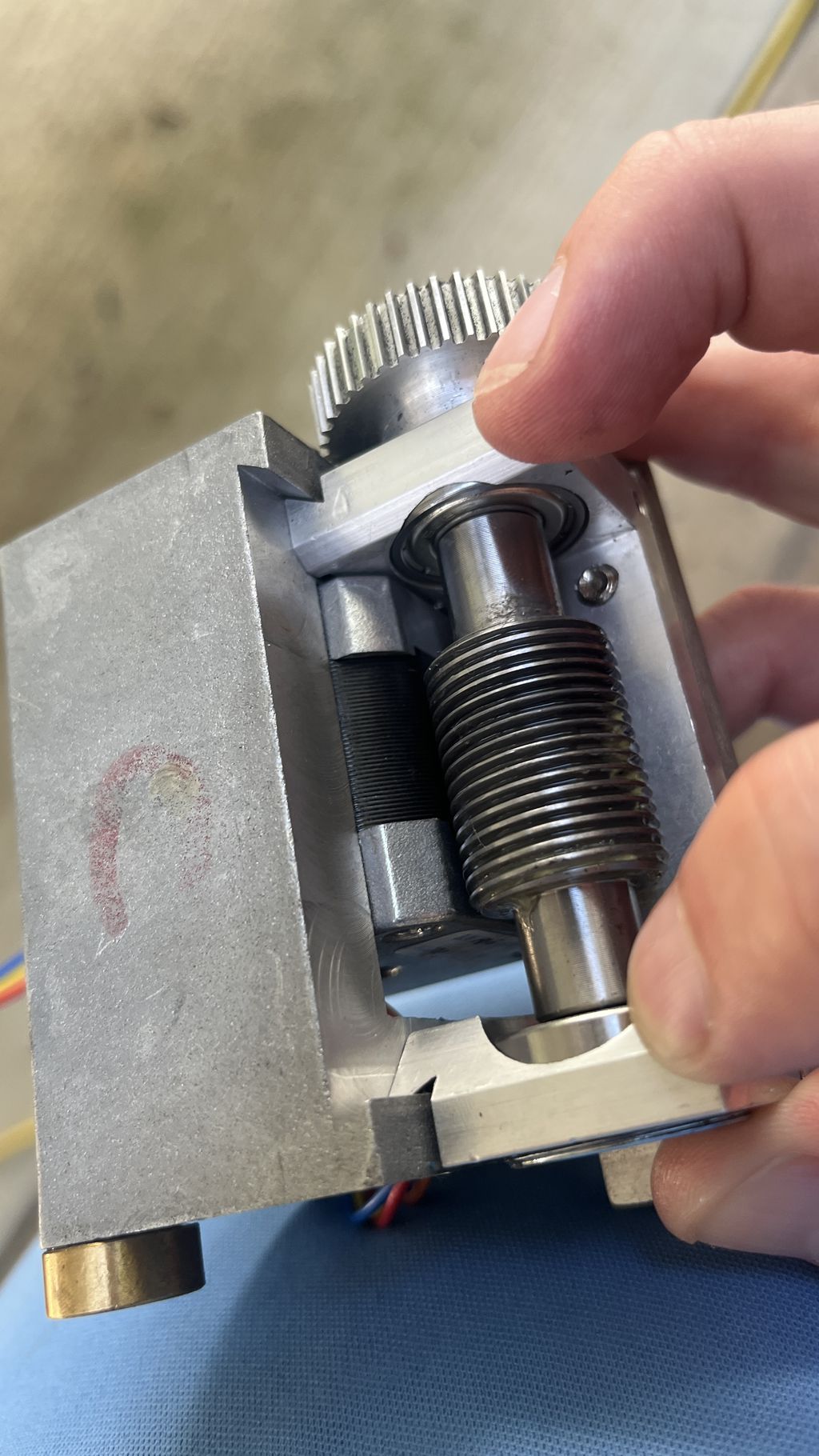

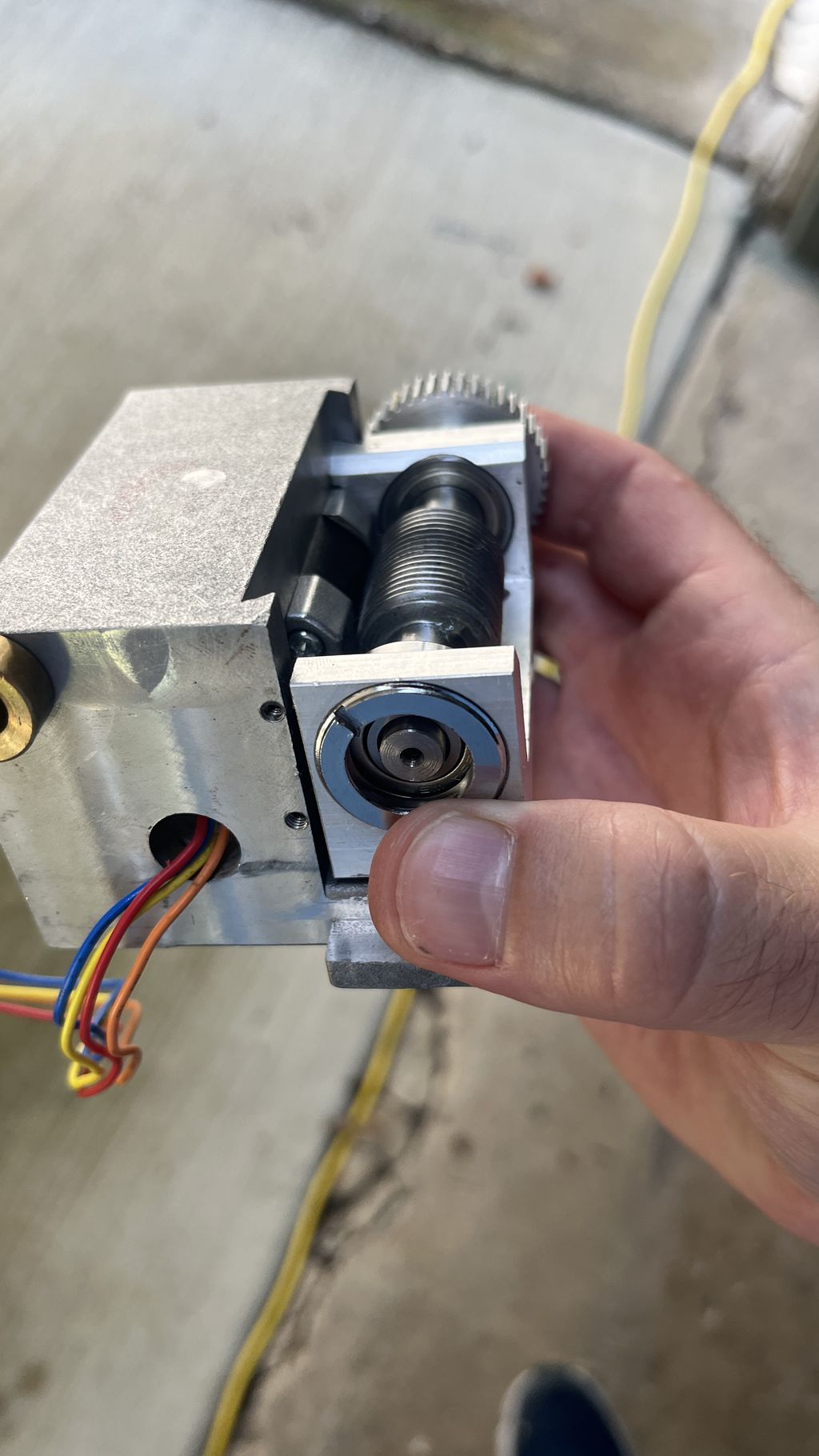

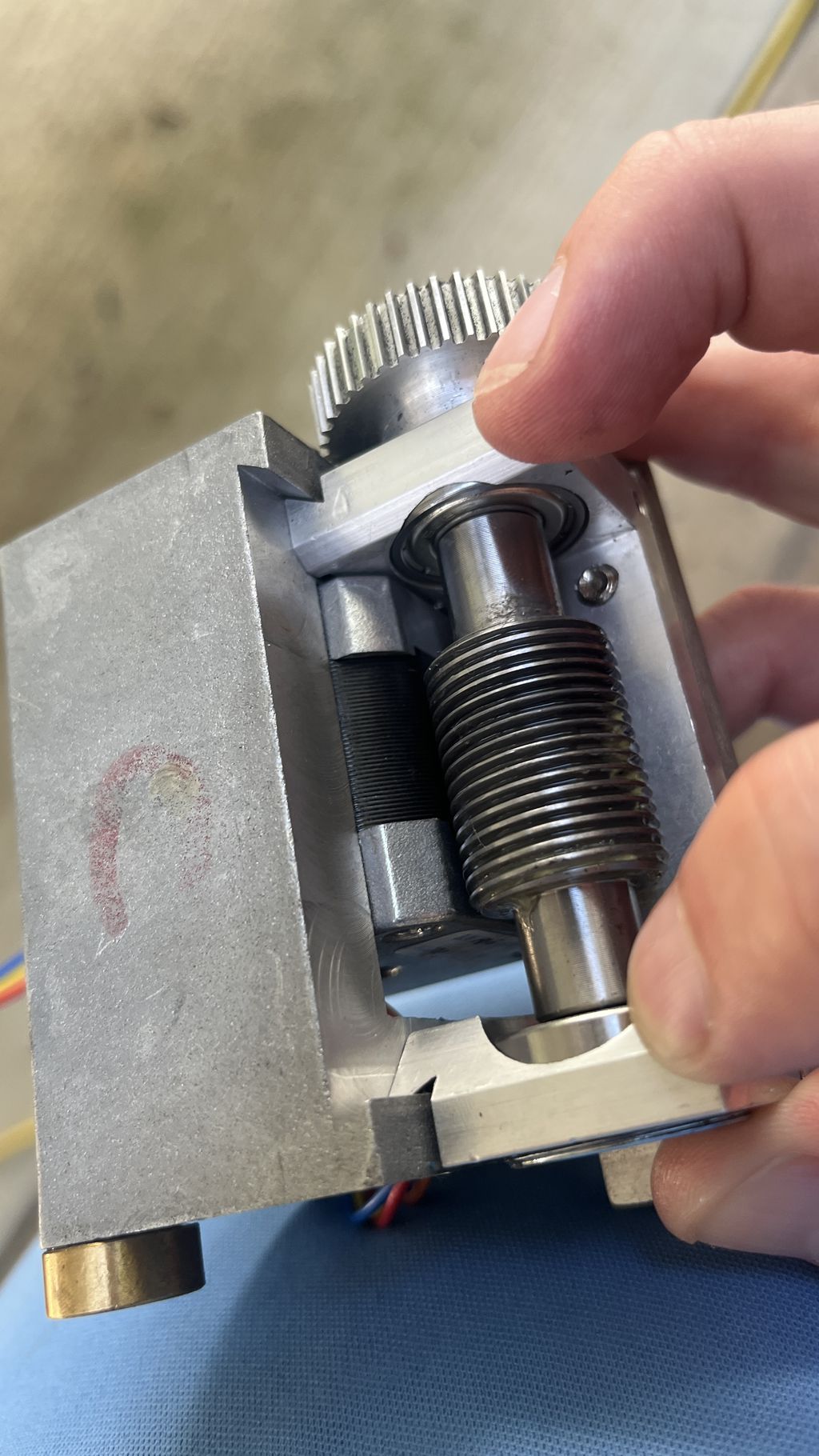

Ok fellas I got it all apart. I’m about to put another little video together showing the last half of the disassembly journey. The two bearings on the worm shaft aren’t feeling as smooth as they should. The bearing opposite the worm pulley had a rough spot in it until I messed with the bearing a little bit. Pretty sure that is the issue. I think the drive was spinning fine and the bearings were hitting rough spots. While I’m all the way apart I’m going to go ahead and replace both bearings and the drive motor. I’ll keep the old as a backup. Going to get new belts for Dec and Ra as well as realign both due to them not tracking straight. I’m going to put in my order now for all the parts. I’ll give the parts breakdown later from skywatcher so everyone gets a good idea of how much everything costs. Wish me luck lol!!!

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Very nice!

Where did you get the tool that you use to disassemble the worm from?

Also a good idea to pull the gears a bit out to avoid contact of the belt with the worm block.

I hope that the new bearings will finally fix the problem!

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I don't know the price difference, but the stock bearings look cheap, and "cheap" in a critical area means questionable performance. Since you're going to replace them anyway I'd suggest an SKF or Barden ABEC 9 If possible (of course it's your wallet, your schedule, and thus your decision).

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I’m definitely taking your advice on the bearings. I got the tool from first light optics. https://www.firstlightoptics.com/rowan-astronomy-mounts/rowan-astronomy-sky-watcher-eq6-neq6-neq6-pro-bearing-ring-retainer-removal-tool.htmlI do have one question. When I removed the locking threaded ring from the wok bearing shaft everything became smooth. The ring was really tight when I broke it loose. I don’t see any thread locker on there but there could’ve been. My question is are you supposed to tighten that ring on the worm shaft really tight? Seems to put the bearings and shaft in a bind where it doesn’t spin freely if tightened too much. Seems like it should just be snug while rotating the shaft to ensure that it does not bind the bearings. This would mean I need to use a thread locker to keep the ring from loosening off. What do you guys think?

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

And man there’s a lot of bearings. Skateboard bearings keeps popping up. I don’t have measurements of the ones on the worm drive but they seem like a pretty common size. I’m going to have to break out the magnifier glass to see what’s on the bearings. I found some abec 11 bearings but look like they’re made for skateboarding. Not sure if it’s the same ones or not. They all look pretty cheap beings I only need 2-4 of them. Skf has a whole different set of part numbers that makes it more confusing for me until I have a number off the old bearing. Any pointers on this as I would definitely like to get the best bearings possible?

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I have two AZEQ-6 mounts and a Celestron AVX and all of these mounts had the same play you experienced. I adjusted the worm gear mesh with instructions found on the internet and was able to solve the issue on them. The procedure is pretty simple but you'll need instructions to help you the first time which might be hard to get for your mount. I understand why the mesh of the worm gear does not get finely adjusted during manufacturing as it takes some time and numerous iterations to get it right. If you can find a service to "hyper tune" the mount, fine adjustment of the worm gear is one of the things they do.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Nick Fritz:

And man there’s a lot of bearings. Skateboard bearings keeps popping up. I don’t have measurements of the ones on the worm drive but they seem like a pretty common size. I’m going to have to break out the magnifier glass to see what’s on the bearings. I found some abec 11 bearings but look like they’re made for skateboarding. Not sure if it’s the same ones or not. They all look pretty cheap beings I only need 2-4 of them. Skf has a whole different set of part numbers that makes it more confusing for me until I have a number off the old bearing. Any pointers on this as I would definitely like to get the best bearings possible? You won't gain much with bearing upgrades. The bearings aren't moving very fast in these mounts and as long as they are not damaged and binding, they are not the cause of poor performance. Fine tuning of the worm gear and making sure the belts are at the right tension goes a long way for these mounts.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Bearing runout is one of the direct causes of periodic error in a worm gear system (the other being worm machining accuracy). The stock bearings "probably" have sufficiently small runout, but a high # ABEC bearing from a top end manufacturer WILL have unmeasurable runout. You want a shielded (not "open" or "sealed") type that exactly matches the ID, OD, and width of the stock unit (buy a cheep pair of calipers to get these numbers or estimate with a scale since metric bearings generally come in 0.5mm increments. Match the numbers you get to the bearing listing in the online McMaster/Carr catalog and use the # on the bearing as a check. The capture ring should be tightened sufficiently to get some end play preload in the worm-bearing assembly otherwise there will be slop in the RA (this might be touchy - you want enough that moving the fully loaded RA axis doesn't have any bonk-bonk). Don't tighten it to the point that the worm binds - it should spin freely. You can use a little blue (NOT RED) locktite to secure it. Clean it up real good and do some practice assembling to ensure there is nothing catching and if you need to undo it at some point in the future a little heat helps release the locktite.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

David Pitou:

Bearing runout is one of the direct causes of periodic error in a worm gear system (the other being worm machining accuracy). The stock bearings "probably" have sufficiently small runout, but a high # ABEC bearing from a top end manufacturer WILL have unmeasurable runout. You want a shielded (not "open" or "sealed") type that exactly matches the ID, OD, and width of the stock unit (buy a cheep pair of calipers to get these numbers or estimate with a scale since metric bearings generally come in 0.5mm increments. Match the numbers you get to the bearing listing in the online McMaster/Carr catalog and use the # on the bearing as a check. The capture ring should be tightened sufficiently to get some end play preload in the worm-bearing assembly otherwise there will be slop in the RA (this might be touchy - you want enough that moving the fully loaded RA axis doesn't have any bonk-bonk). Don't tighten it to the point that the worm binds - it should spin freely. You can use a little blue (NOT RED) locktite to secure it. Clean it up real good and do some practice assembling to ensure there is nothing catching and if you need to undo it at some point in the future a little heat helps release the locktite. I agree with you on it being the cause of periodic error but the OP is experiencing erratic performance between 5s guide pulses.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

David Pitou:

Bearing runout is one of the direct causes of periodic error in a worm gear system (the other being worm machining accuracy). The stock bearings "probably" have sufficiently small runout, but a high # ABEC bearing from a top end manufacturer WILL have unmeasurable runout. You want a shielded (not "open" or "sealed") type that exactly matches the ID, OD, and width of the stock unit (buy a cheep pair of calipers to get these numbers or estimate with a scale since metric bearings generally come in 0.5mm increments. Match the numbers you get to the bearing listing in the online McMaster/Carr catalog and use the # on the bearing as a check. The capture ring should be tightened sufficiently to get some end play preload in the worm-bearing assembly otherwise there will be slop in the RA (this might be touchy - you want enough that moving the fully loaded RA axis doesn't have any bonk-bonk). Don't tighten it to the point that the worm binds - it should spin freely. You can use a little blue (NOT RED) locktite to secure it. Clean it up real good and do some practice assembling to ensure there is nothing catching and if you need to undo it at some point in the future a little heat helps release the locktite. Yes this is exactly what I was talking about. The amount of torque to put on the work bearing shaft. It needs to be tightened enough so that the shaft assembly is secure without play but free to spin smoothly without any binding. This was the issue with the 60s or more or less Ra spikes. Everything else in the assembly feels smooth like the idler for instance. The drive motor is a motor so spinning is by hand doesn’t really tell you much. This is a picture of the locking ring that needs to be set correctly to ensure smooth guiding as I see and understand it especially after having the issue I had and analyzing and breaking it all down to feel and check it all. The amount of tension on that locking ring nut sets these two bearings and I believe mine was over tightened. And update I have all the parts coming for 195$ total. 4 bearings, 2 belts, 2 worm block brass bushings, 1 Ra worm drive motor, and 1 Ra worm Block bolt.   |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

The bearing skywatcher uses in the CQ-350 is a 608z jesa w5 bearing. Couldn’t find the quality of that one in a search. I think 608z is a size and it’s super common. This one does not show the abec number. I have some abec 7 bearings but noticed they pinched when tightening which made me think hmmmm I probably need blue loctite and I need to set the tension by hand so it spins super smooth.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Ok so after some research I found that the bearings skywatcher uses are called Jesa W5 bearings. They are 608z which is 8mm ID 22mm OD and 7 mm thick. The brand Wicked teamed up with Jesa to make performance bearing both steel and ceramic and they are supposed to be high performance and long lasting. So the originals are supposed to be good. I think there might be a guilty party tightening them down too much just to be safe but this caused it to bind. I have 4 coming both both worms since I grenaded the mount. I also have some abec7 bearings made by Tonmp and I don’t know if I can trust those.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.