Very interesting that these thread has just "lit up" again as last night my CQ350 had another, more serious, episode. 4-8arcsec oscillation in RA (time period few secs) when pointing north (dec -20 and above - I live at -45S). Difference positions in the northern sky (east and west of the pier) showed the same problems - in the south of the sky - no serious issues. Other scopes working at the time - no issues. Including those working outside enclosures. Conditions clear, light winds. Anyone seen this. It certainly seems mechanical and it looks like I will be following @Nico Gärtner video closely. Thanks Nico. CS Brian

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Nick Fritz:

Yes you are absolutely right. I did take off way too much. I couldn’t tell from just looking and I really wanted to find the noise/issue while opened up and still connected. I knew I would do some things that were unnecessary in the end but now I know lol.

I very much appreciate your response because it does get me going in a direction now and I believe the right direction. Skywatcher has just dropped me basically. I work in customer service so I am very patient and not rude about things. For whatever reason they are not communicating or letting me buy parts as crazy as that sounds. So I need to basically remove the rest of the worm block and source the parts I need. If it’s the drive motor then the eq6 will work? I’m assuming those can be found. Also I have one more question for you. On that ra cover plug, how do you remove it? It unscrewed half a turn and stopped. Does it pull out or I gotta keep unscrewing?

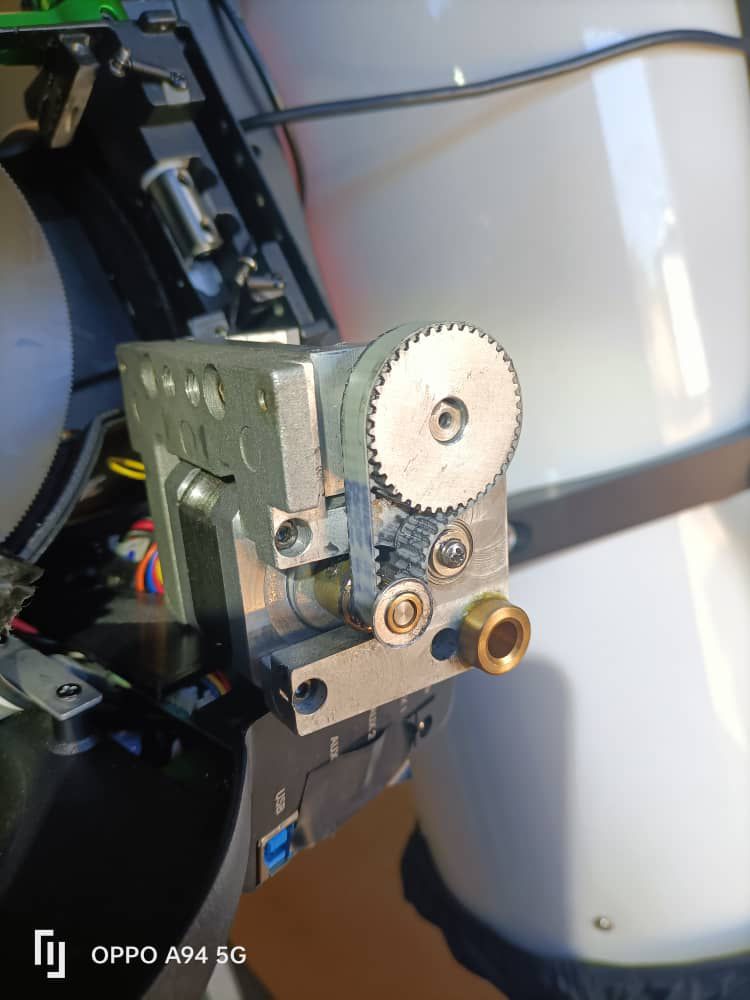

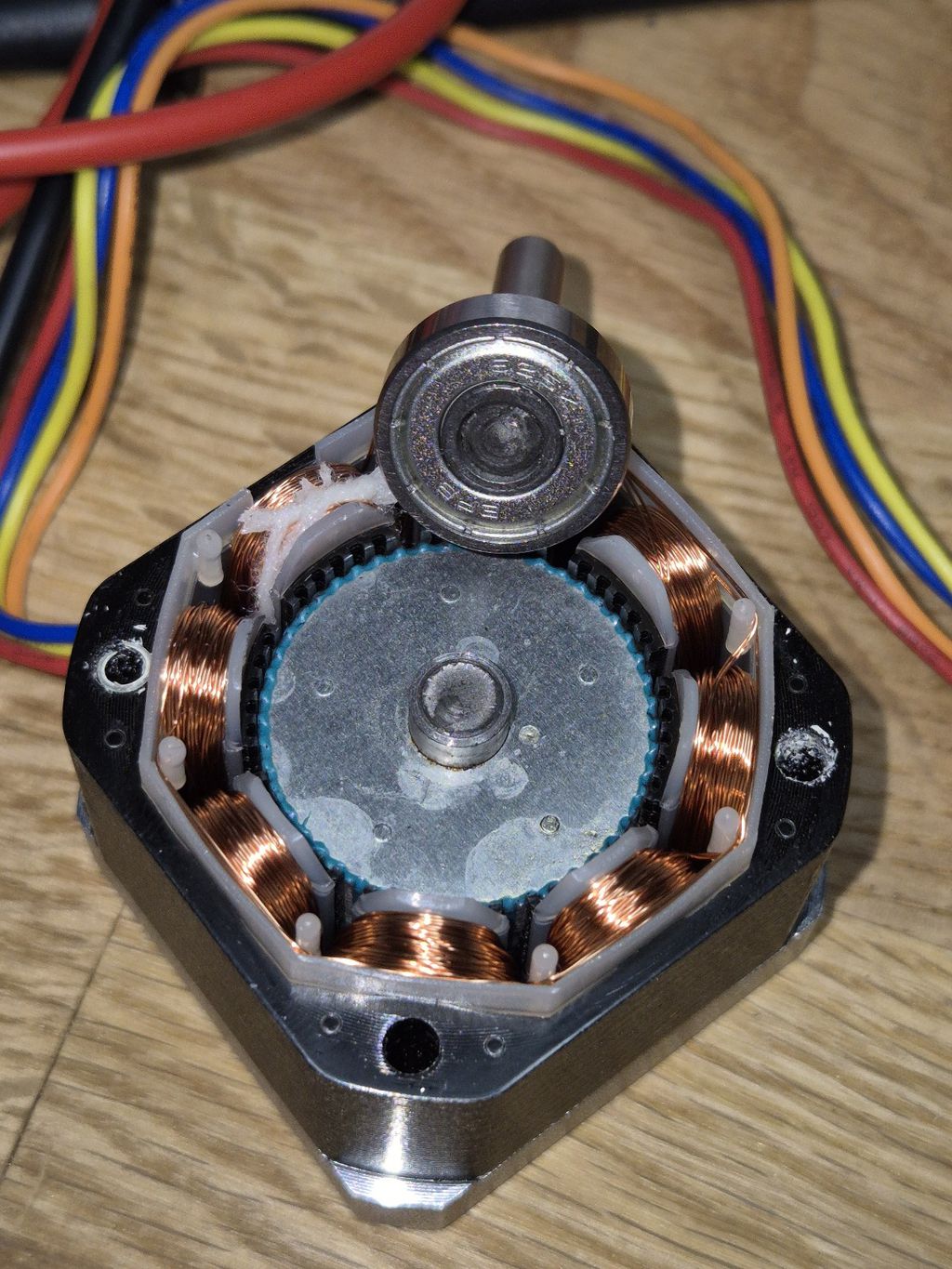

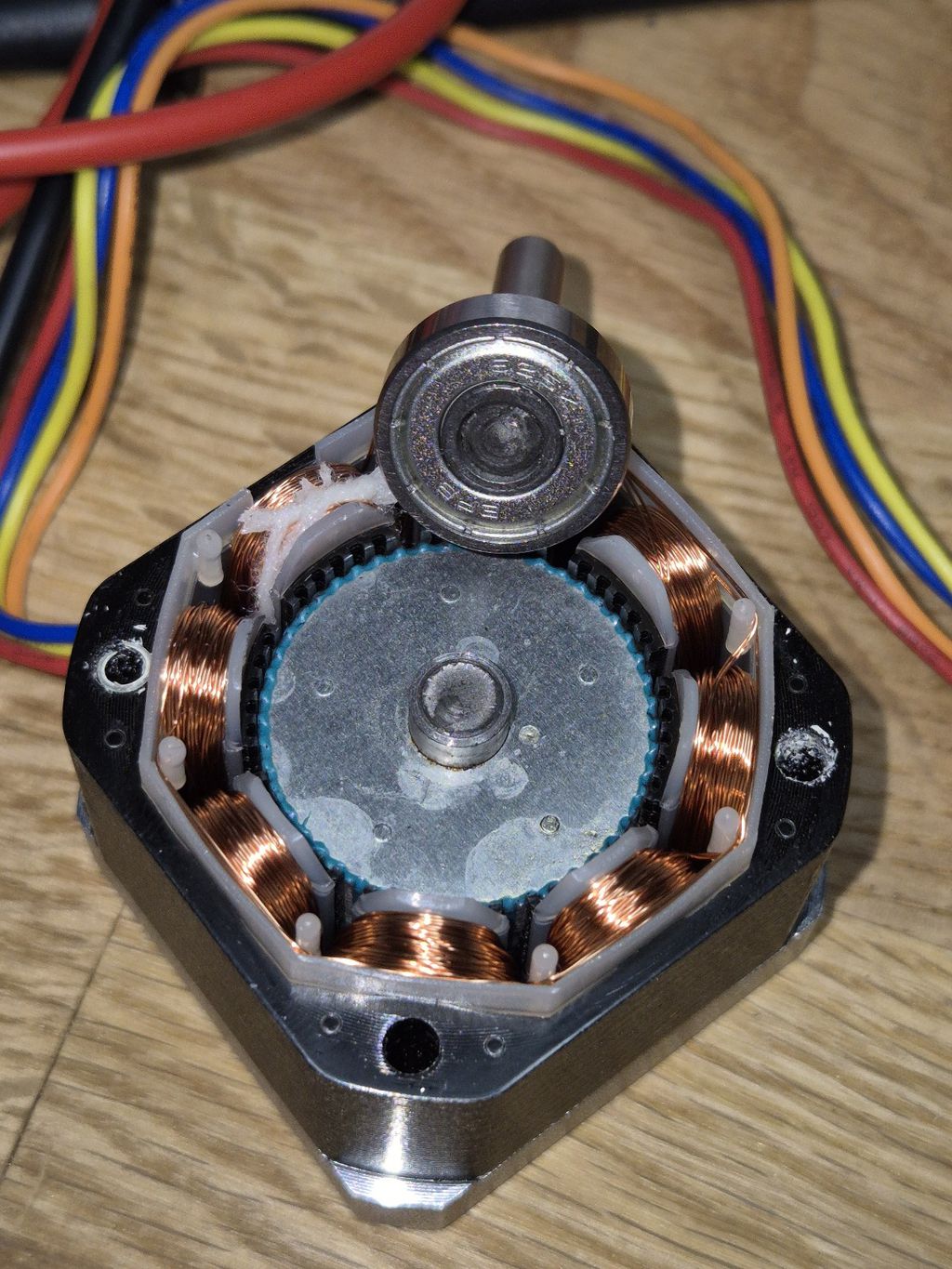

Thanks again as your knowledge is very valuable. I will shoot more video on this as I remove more and replace the parts to get going again. Also you described the issue perfectly as well. Likely you have the same thing happening that I do. Hi Nick, this "RA cover plug" is just screwed in - if it jams in the thread give it a shot of WD40 and try to wiggle it back and forth to come off. Behind it is a bolt that goes through the brass coloured part - it can be unscrewed - afterwards you are able to pull out the whole RA unit including the motor. See below... and note how "shitty" the cheap belt looks after 8 months of intense use - we replaced it by a quality belt afterwards.  And here's an image of our motor, which was jamming - after opening the housing the shaft just fell apart!  @Brian Boyle @Brian Boyle - note that the video on youtube is from @Nick Fritz ... i am just giving input here because I am sharing the same fate and gained some experience already ;-) The major difference is that @Nick Fritz is able to work on his mount at home, while I would need to travel 11.000 km to the Namibian desert - therefore I really keep fingers crossed (or my thumbs pressed, as we Germans say) that he is able to fix the problem so that we all can learn from his experience. CS Nico

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Wow I can’t believe that shaft just broke. That’s wild. Ok so I don’t even have to take the 4 Allen screws that adjust the worm to ring mesh? I need to get that plug off and unscrew that brass bolt and remove the unit. I will make sure to document it so that hopefully it can help someone. It could possibly even help your people out in Namibia. It’s not fun wondering if you’re doing it right lol. My issue was exactly as described by Nico. It was a consistent issue more or less depending on the pointing in the sky. After zenith was not as bad as before but still the same issue. Thanks so much for responding again and I will respond back here for sure when I update the video with the worm drive out.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Hi Nick,

A basic RA drive error Root-Cause discovery method is:

A. Is the sound and/or guiding error spike mostly regular (you're golden) or mostly irregular (more difficult)

1. Regular:

a. Is the frequency of the sound/spike equal to the Motor - remove and decide if it's the motor pully or the motor and replace it.

b. " " Worm - look at the worm and pully to decide which, if pully - replace it, if worm - try adjusting further into the ring (don't go so far as to bind it) or more spring loading (too much and it will chatter or bind while turning), then PEC

c. " " Belt (mark and time it, or just watch) - replace the belt

d. " " Idler/tension pully - take it apart to see what's bad in the assembly and replace it

2. Irregular (something is moving and you need to decide what):

a. Is the click/spike associated with Wind - check for worm axial play (there should be a adjustment for this), try adjusting the worm further into the ring, more spring loading, scope balance

b. " " Gravity loading (which side of the pier the scope is on) - re-balance the scope (if it's a fork mount try overloading East or West side to see if it helps (German can't do this) check for worm axial play, try adjusting the worm further into the ring, more spring loading

c. " " reversal or speed change - too much axial play in the worm, or play in the gears (if any)

d. Occurs throughout the worm rotation - grit inside the motor - replace the motor (because of the magnets they are impossible to clean)

3. Worm chatters or doesn't turn - something is taking more torque than the designer counted on - worm is being pushed too hard into the ring, grit on the belt, bad bearing

I don't know where you are located, but if you're in the southern US (accent!) try McMaster Carr for everything (belts, pullies, bearings) but the worm and worm block (manufacturer or custom only). Just take it apart, get a number and call them.

Nico, the motor shaft broke at a groove (read stress concentration) at the point of highest moment. I would suspect too high a belt tension and I'm surprised the bearing nearest the break didn't go bad first.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Hi

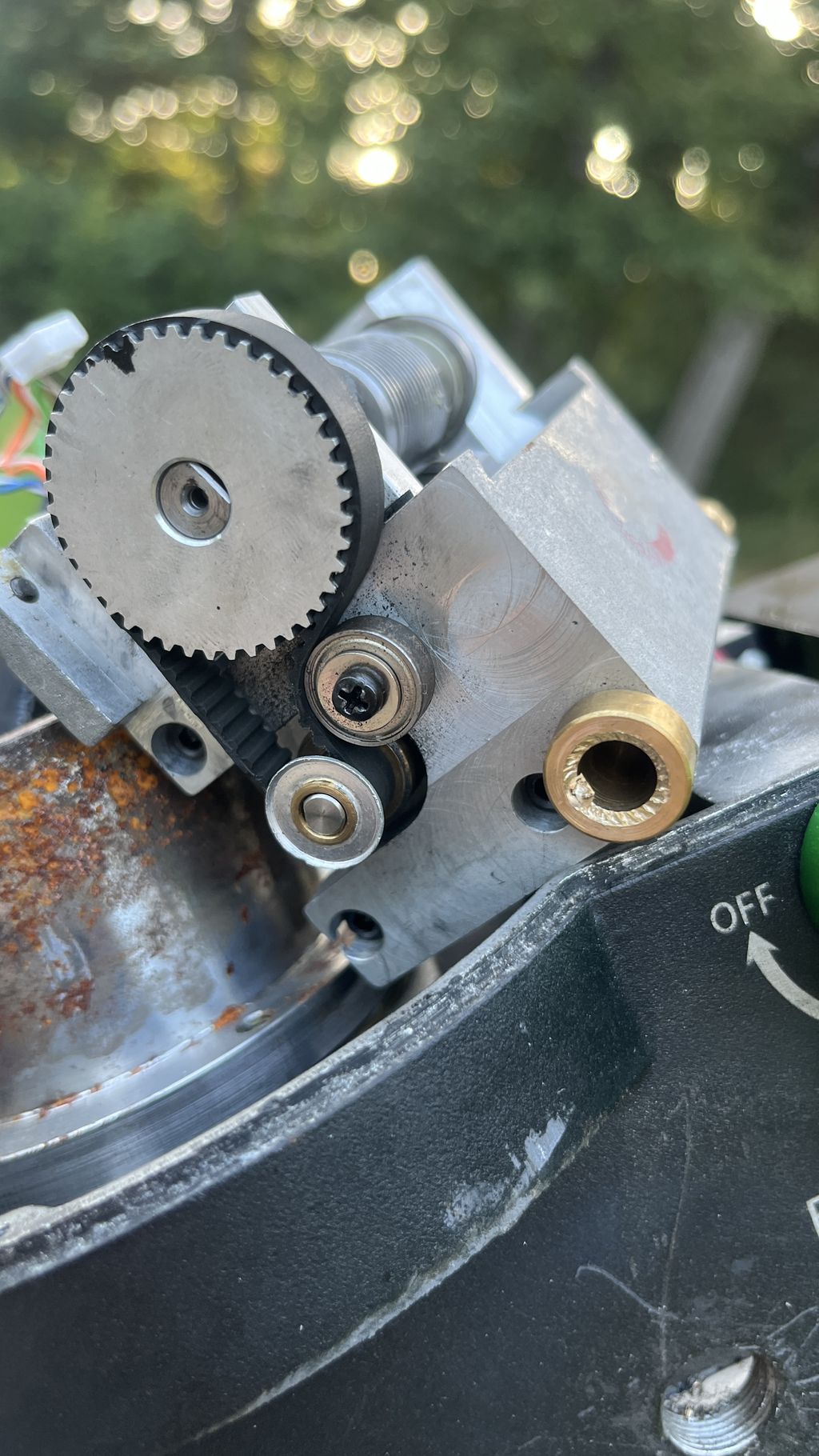

Bumping into the discussion, as I am facing a loose belt on the RA block, if I understood well the block goes out easily … but to do so how do you remove the front teethed wheel ?

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Nicolas Godingen:

Hi

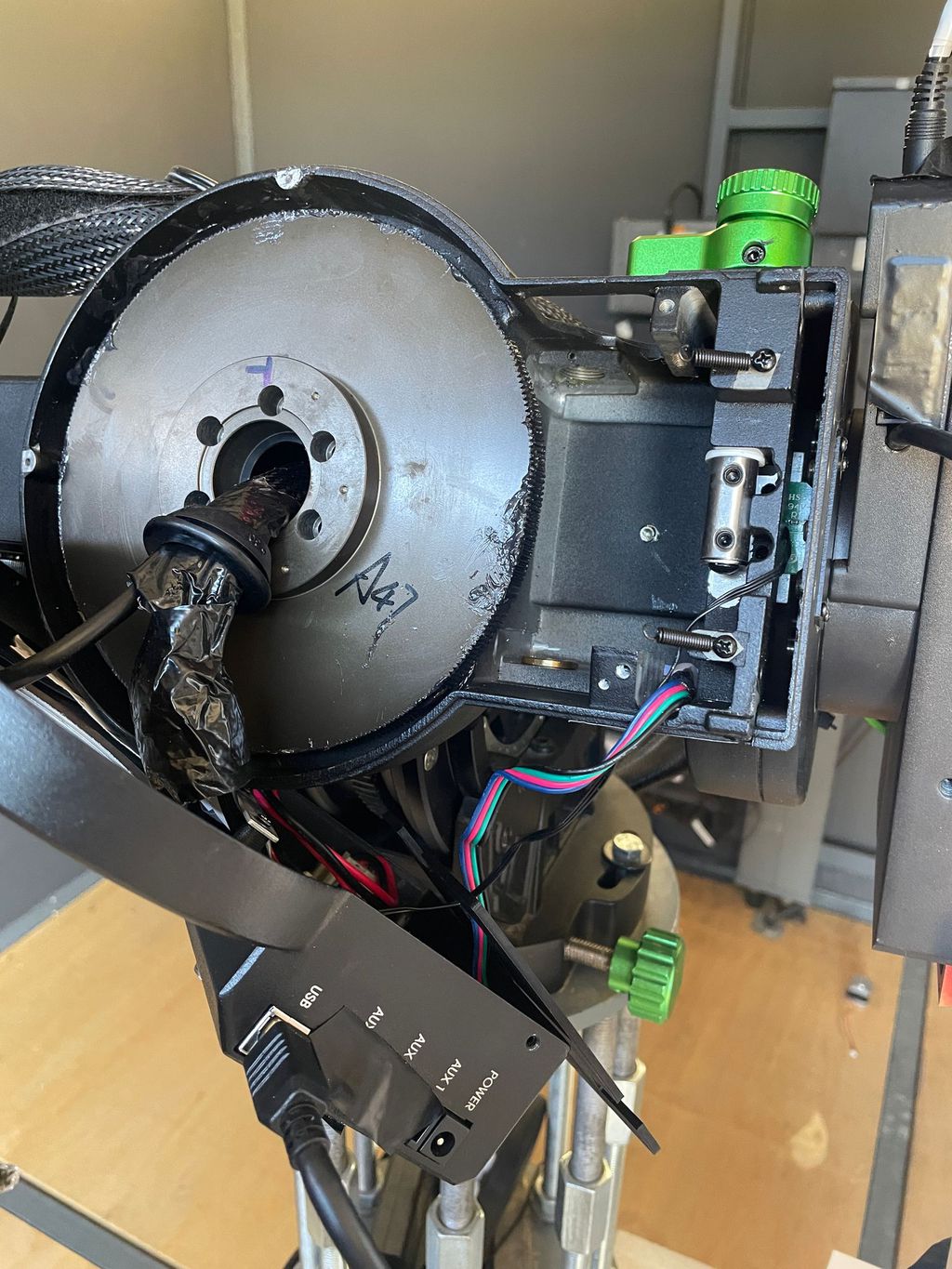

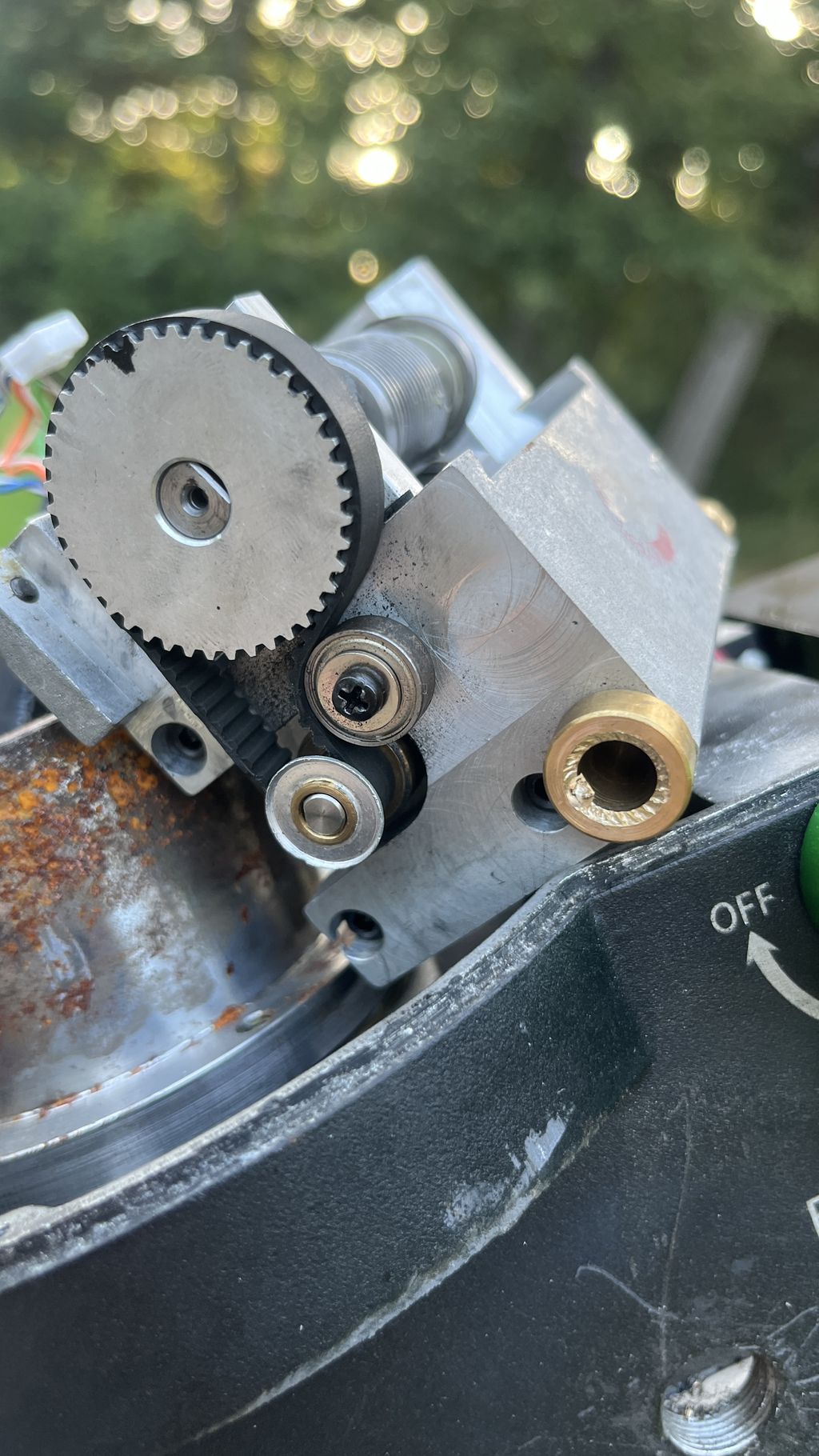

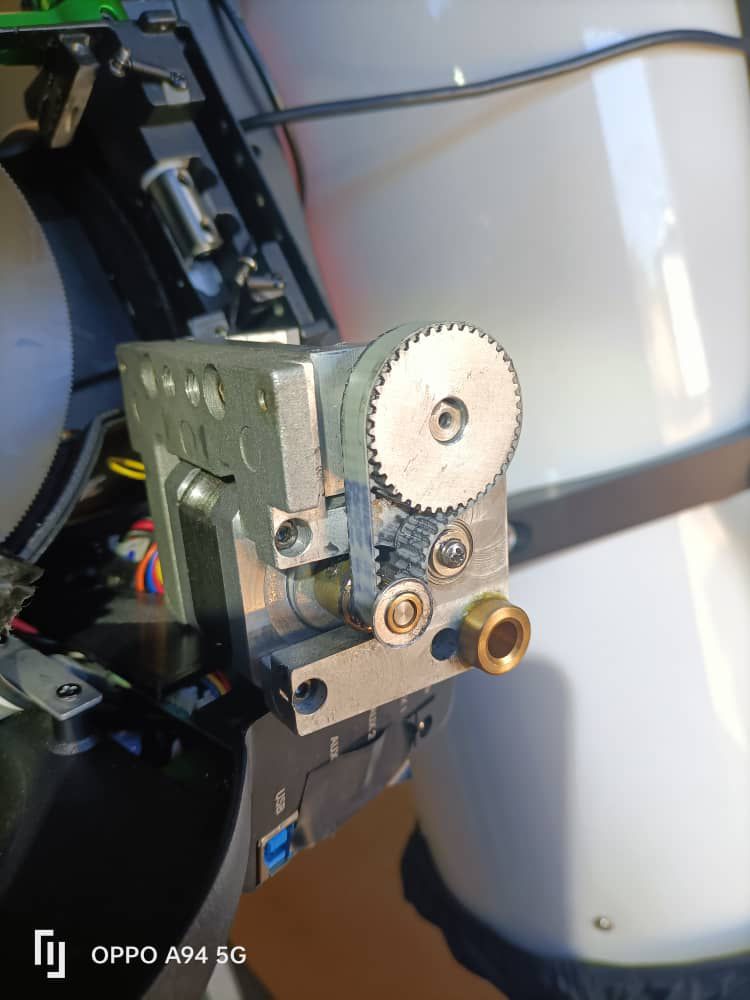

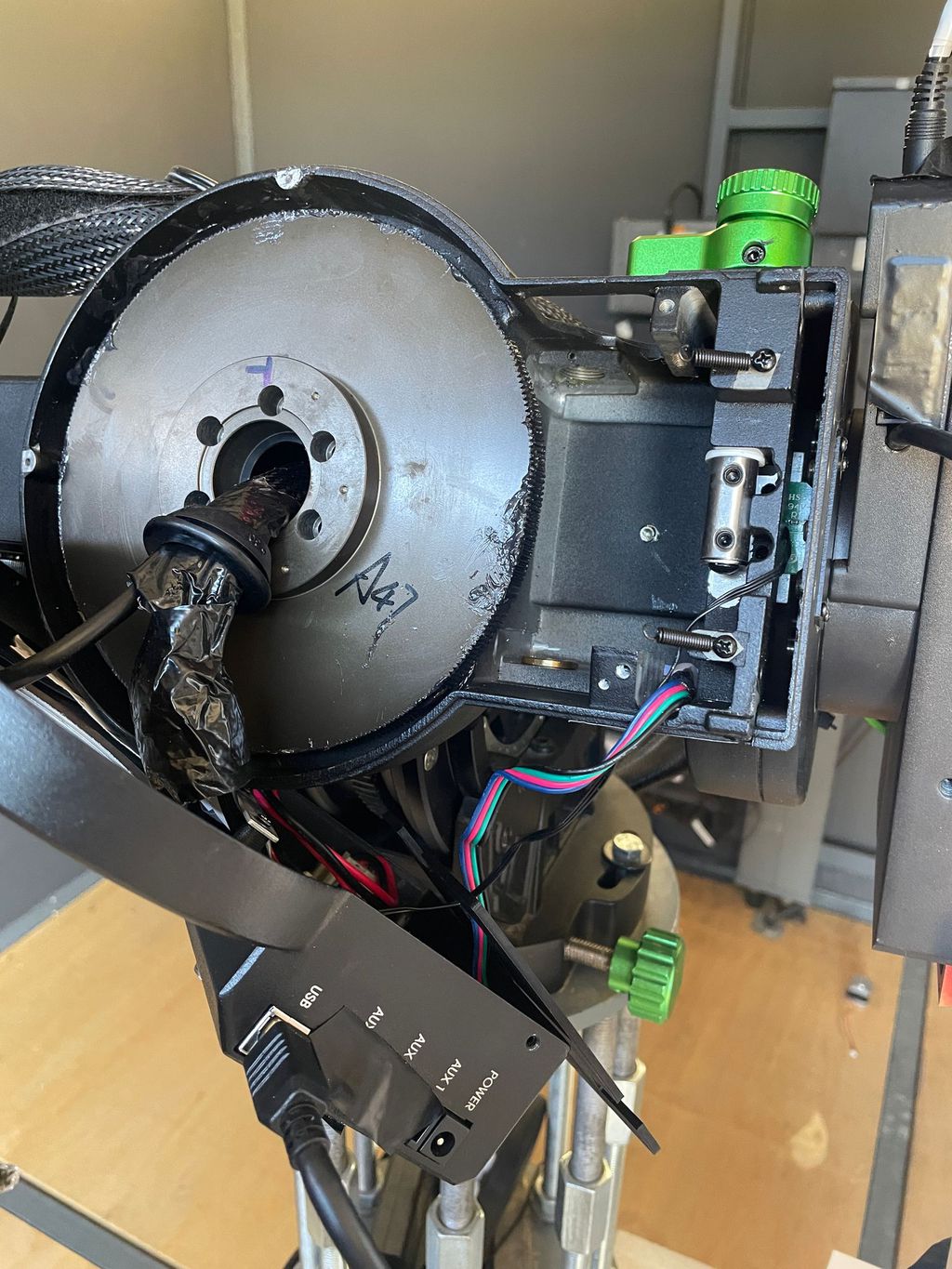

Bumping into the discussion, as I am facing a loose belt on the RA block, if I understood well the block goes out easily … but to do so how do you remove the front teethed wheel ? The main RA wheel is held in place by 6 screws which are easy to remove. Its advisable, but not really necessary to remove the wheel by the way... I found a pic of the moutn with the RA block removed...  The inability to remove the belt easily in this mount is actually one of its biggest design flaws... hopefully one day I meet the guy who came up with this, and tell him how many hours we spent to figure out how to replace the belt.  If your belt is just slack, you can try if you get it tensioned though the small "RA service opening" on the side, but I think that the bearing that they use as tensioner cannot really be adjusted - its just held in place by cheap screw and a shim.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Nick Fritz:

Wow I can’t believe that shaft just broke. That’s wild. Ok so I don’t even have to take the 4 Allen screws that adjust the worm to ring mesh? I need to get that plug off and unscrew that brass bolt and remove the unit. I will make sure to document it so that hopefully it can help someone. It could possibly even help your people out in Namibia. It’s not fun wondering if you’re doing it right lol. My issue was exactly as described by Nico. It was a consistent issue more or less depending on the pointing in the sky. After zenith was not as bad as before but still the same issue. Thanks so much for responding again and I will respond back here for sure when I update the video with the worm drive out. I think the shaft was loose all the time - they probably already broke it at the factory. After a couple of months we were experiencing step loss during fast slews and then the torque went down. Basically the shaft was just held together by the pressure of the casing. Sourcing a replacement was actually easy, but finding the error was tough - as I wrote above the CQ350 uses the same motors as the EQ6-R and they are sold by some shops.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Nico Gärtner:

Nicolas Godingen:

Hi

Bumping into the discussion, as I am facing a loose belt on the RA block, if I understood well the block goes out easily … but to do so how do you remove the front teethed wheel ?

The main RA wheel is held in place by 6 screws which are easy to remove. Its advisable, but not really necessary to remove the wheel by the way...

I found a pic of the moutn with the RA block removed...

The inability to remove the belt easily in this mount is actually one of its biggest design flaws... hopefully one day I meet the guy who came up with this, and tell him how many hours we spent to figure out how to replace the belt.

If your belt is just slack, you can try if you get it tensioned though the small "RA service opening" on the side, but I think that the bearing that they use as tensioner cannot really be adjusted - its just held in place by cheap screw and a shim. That’s weird as my mount doesn’t seems to have this access door on the side of the mount … On mine the belt is really loose … you can suppose move it by hand.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

So that pin that holds the worm block in on my mount is stuck in there bad. The Dec one comes right out. I ordered a eq6 worm bearing removal tool that looks like it’s made for the two hole bolt head that holds in the worm block. I would really like to replace that pin if I can ever get it out but I can’t find it anywhere.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

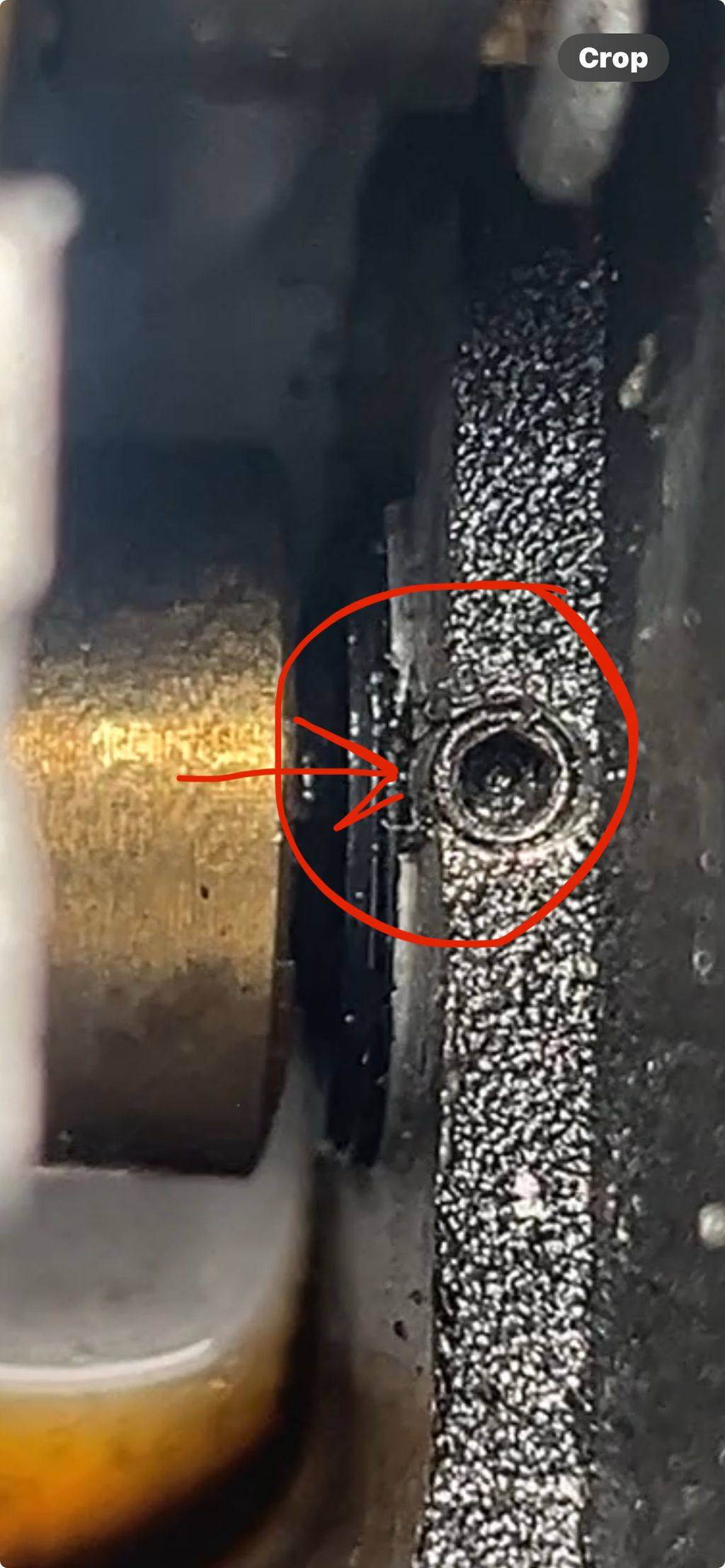

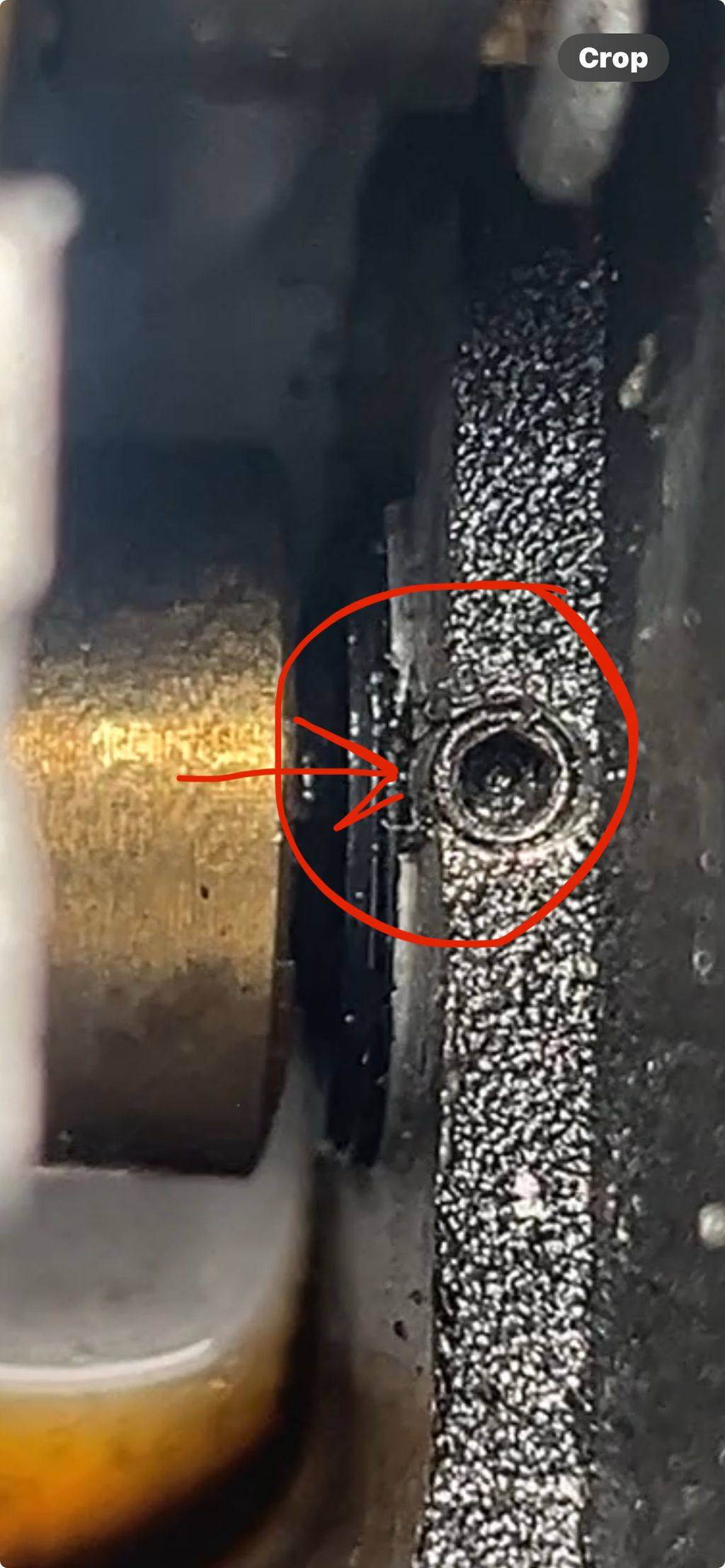

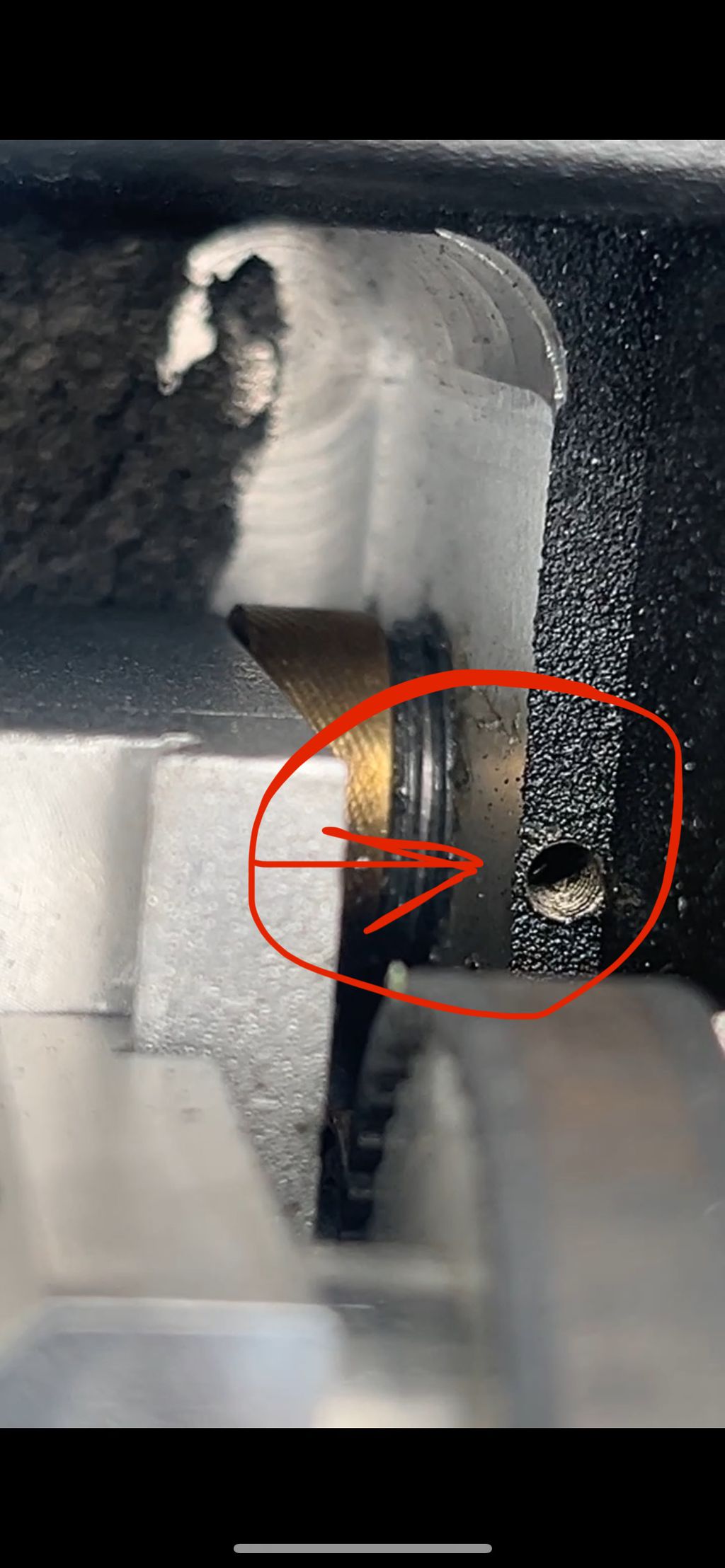

In Niko's picture (which seems to be a different CQ350 version from yours) it looks like there is a locking set screw that needs to be backed out before pin removal or you'll gall it.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

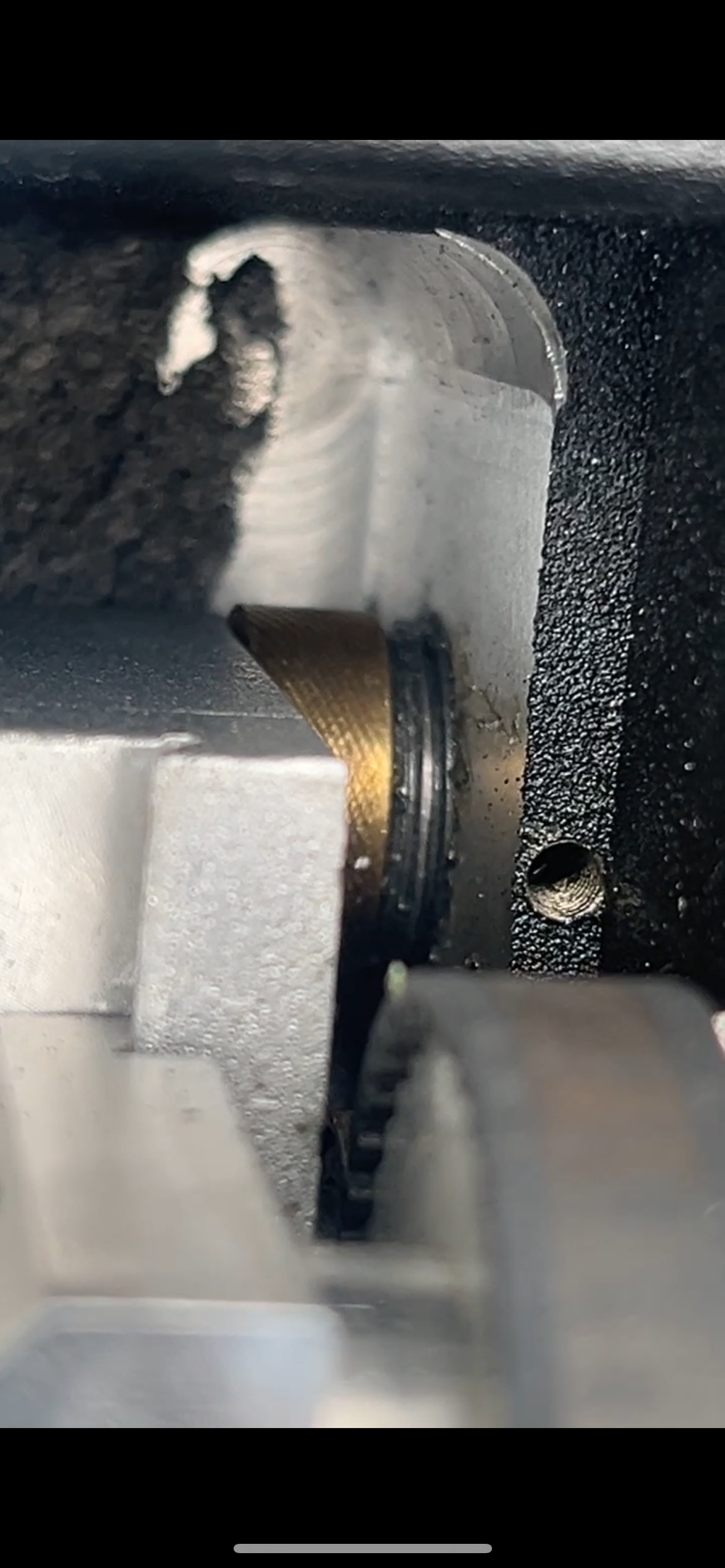

@Nick Fritz : This is what @David Pitou is refering to.  Another BS design IMHO, because the grub screw will damage the thread.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Nico Gärtner:

@Nick Fritz : This is what @David Pitou is refering to.

Another BS design IMHO, because the grub screw will damage the thread. Yeah I have stuck every size Allen I have down that hole and it appears there’s nothing in there. The Dec bolt came right out but the RA is not. I’ve looked in the hole too and it looks like a threaded hole with nothing in it. Oh this mount!!!

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Nick Fritz:

Nico Gärtner:

@Nick Fritz : This is what @David Pitou is refering to.

Another BS design IMHO, because the grub screw will damage the thread.

Yeah I have stuck every size Allen I have down that hole and it appears there’s nothing in there. The Dec bolt came right out but the RA is not. I’ve looked in the hole too and it looks like a threaded hole with nothing in it. Oh this mount!!! Have you used metric allen keys?

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Nico Gärtner:

Nick Fritz:

Nico Gärtner:

@Nick Fritz : This is what @David Pitou is refering to.

Another BS design IMHO, because the grub screw will damage the thread.

Yeah I have stuck every size Allen I have down that hole and it appears there’s nothing in there. The Dec bolt came right out but the RA is not. I’ve looked in the hole too and it looks like a threaded hole with nothing in it. Oh this mount!!!

Have you used metric allen keys? Yes I have. I ordered a new set to try again. My eyes tell me that hole is empty on both bolts but I’m going to stick everything I can down there while I wait for this eq6r worm socket to show up. Hoping the holes are the same on this bolt as they are on the socket. Anyone have any ideas where to get a new bolt just incase? I should be able to repair and make this one work again if it ever comes out.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Can you post a picture of the DEC one? My guess is it looks like it would be custom which means factory or your local machine shop. You can just take it in and have them duplicate it. Won't be cheep (unless you plead your case like an academy award actor or send your wife), but may be worth it. Repair would be cheaper - just get a GOOD set of needle files and take your time.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

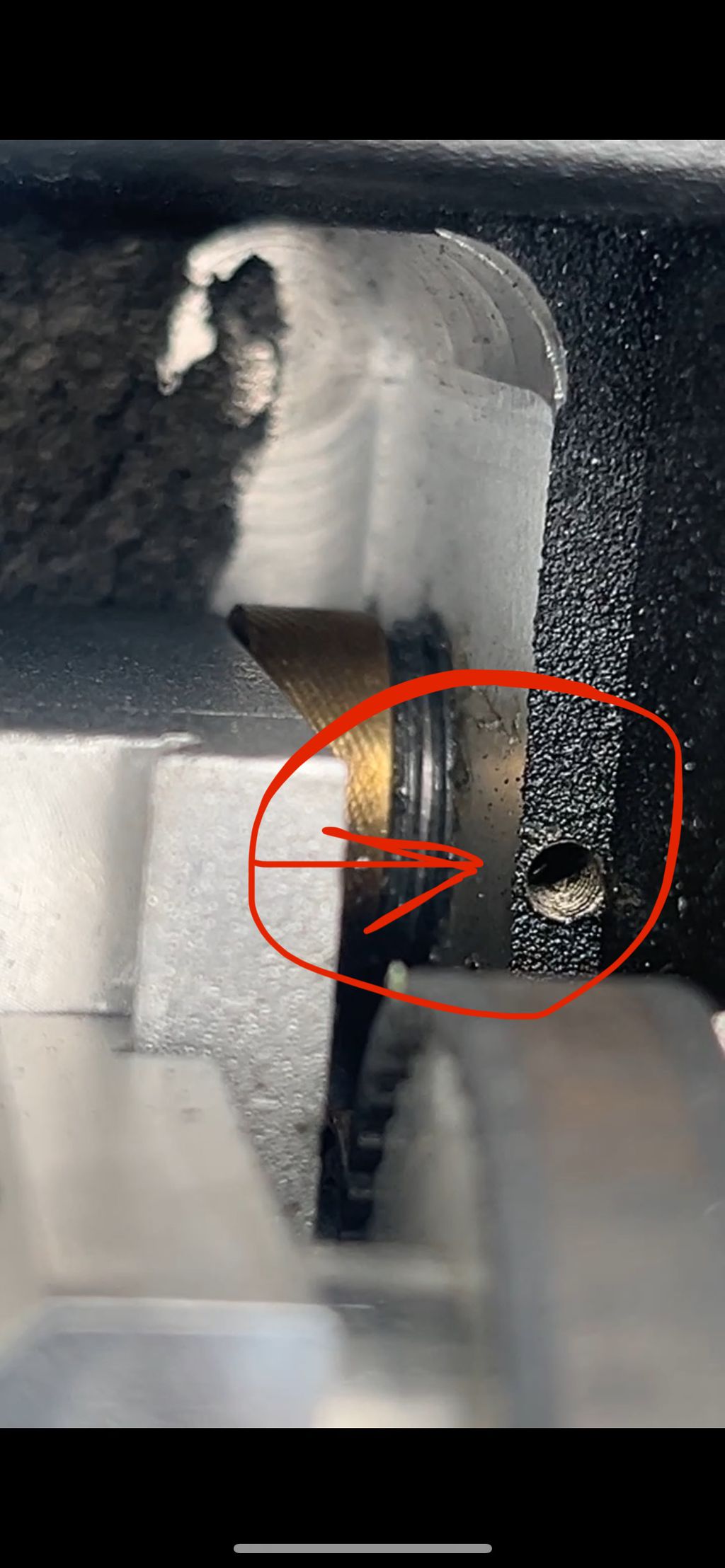

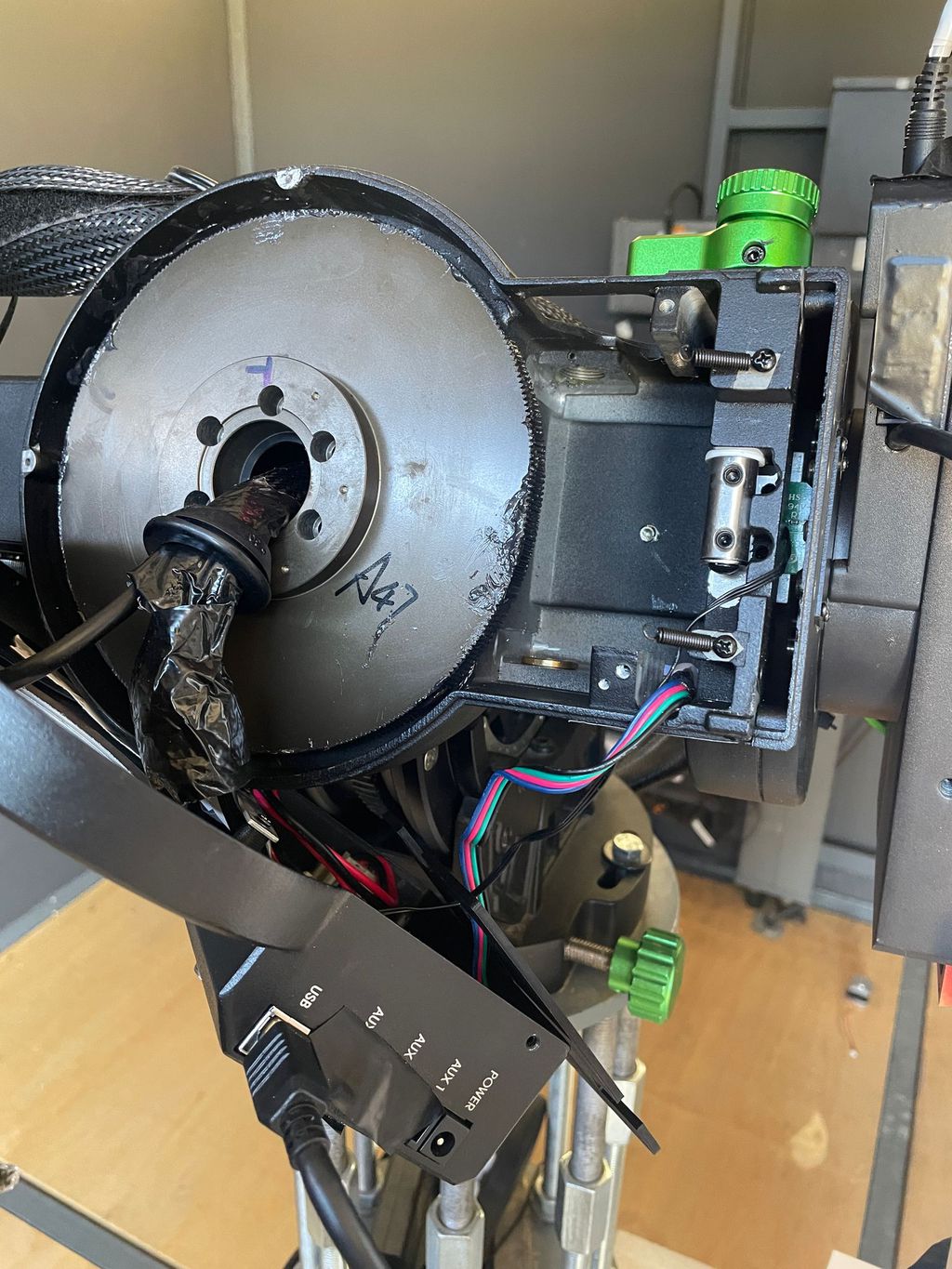

I just got some more pictures from our mount. Here you see how he bolt looks like, when it is removed. Looks like the have put lots of black paint on the threaded part, which can make it very difficult to remove once it is screwed in. Can you send a picture how yours looks like now?  |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

By the way: if the EQ6 tool does not work you can also go to your local hardware store and show them a picture - they should have the right tools.

You can also go to amazon and search for "Circlip pliers/snap ring pliers" - I think these should do the job.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

That's custom, so repair would be best. Can you get it to rotate at all? If no - wait for the socket or you'll just bugger up the holes (looks like they shouldered, jammed, or black-paint glued it to hold it in place instead of using that stupid set screw, so a lot of torque is going to be needed for removal), if yes - spray it with some WD40 along as much of it's length that you can get to and work it back and forth a bit (be careful of the holes). If you can get a bit more rotation keep working, if not, again just wait.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

David Pitou:

Can you post a picture of the DEC one? My guess is it looks like it would be custom which means factory or your local machine shop. You can just take it in and have them duplicate it. Won't be cheep (unless you plead your case like an academy award actor or send your wife), but may be worth it. Repair would be cheaper - just get a GOOD set of needle files and take your time. When my tool arrived and I uncover it again I absolutely will. I intend on shooting some more videos that show how to do this. I used to work fastener company and we made stuff and had things made so I might try them if I can clean it up real nice. It’s the head with 2 holes in it that kills me lol. A spanner wrench is too wide and the pins are all too big. Silly design I think. Should’ve been an Allen head inset like everything else. I’ll get there eventually.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Hard to tell from your closeup, but it looks like the belt isn't tracking correctly (it's protruding over the edge of the pully) which is a wear issue and if there is some edge runout can it intermittently touch another surface (may be the cause of your spike)?

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Notice how the first picture you can see the pin and the second one you can’t? They did not do a good job job drilling the lock screw hole on the Ra. See how you can see the pin? It should be in its screw hole but 1/4 of the hole is exposed. This should’ve never left the QC table. The belt definitely is not staying centered The noise I’m hearing and spike I’m getting is most certainly going to be from a hard part failure My tool just landed in America so hopefully I get it soon and can remove this Ra worm drive pin to get to the root cause I was just pretty surprised Skywatcher let this go as good when I would’ve said whoa whoa whoa Who drilled that hole? You missed!! Start over with another one cuz that’s not gonna cut it   |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Good news is the bolt is out!! Bad news is it took a lot to get it out. It is out now and the worm block quit making the noise. The worm drive feels rough when operating the ra drive so I believe I will be ordering that along with a belt and a new bolt for the worm block. Skywatcher said something like 45$ for the bolt. I am going to take the idler pulley off tomorrow to get the belt off to free spin the worm shaft and ra drive and see if that tells me anything else. One question…. Do you guys just cut and solder the wires in for the new ra drive motor? Thanks a bunch and will be posting again soon.   |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Hi @Nick Fritz, congrats to the creative solution, and ouch... it looks like that bolt and the brass part on the RA block is damaged - you should definitely file that brass chip off. Regarding the motor cables: You can simply unplug the motor cables from the control board - just make sure to remove the hot glue bits on the connector as good as you can (maybe heat it a bit using a hairdryer). Do not wiggle or pull with force, because you can easily rip off the connector from the board (I know what I am talking about...). By the way it looks like this hole is also not drilled correctly...  seems so be a general thing... ours also looks weird at second sight.  |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.