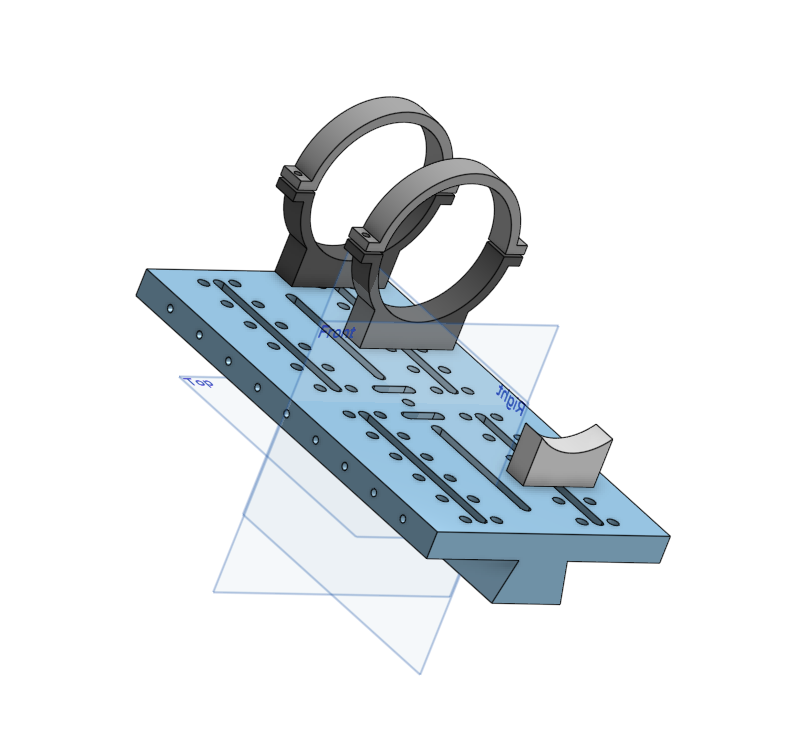

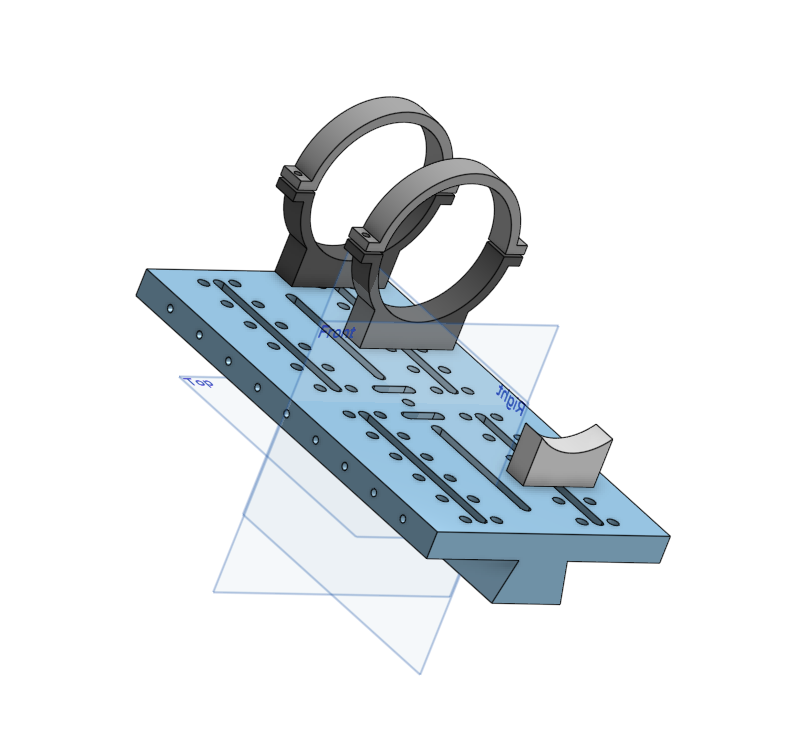

Hi all. I am in the process of learning cad and I thought a good place to practice was making a dovetail plate, and some mounting rings for my set up. My question is for those who also have 3d printed parts and accessories. What filament would be best to use for a lightweight setup? I have a 585MC PRO and I want to match it up with some of my lenses that I own. plus a guide scope and asi air plus. I am prototyping in tough pla and it feels sturdy enough but I am not sure how it will behave in the cold of night. anyone else have experiences with this. I see plenty of people using carbon fiber infused filament but I dont have the experience with that stuff yet.  |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I don't know how PLA is in the cold but it will deform if it gets too hot. I have had PLA do this in a garage or on a car seat during the summer. Honesty, I think I would make a saddle plate out birch plywood before I would trust PLA.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

It can really vary material wise what you need expectation wise and what hardware you have as well.

PLA, PETG or PETG-CF are some the lower end material in terms of strength but work fine depending on what you are needing. PLA though can be really really weak, especially in temp changes and if sun hits it. Again, depends on many variables like thickness of print, surface area, etc… but I would probably use it for prototyping and that's it, move on to better materials for astro gear. Nice thing about some of these materials is most printers will print them fine, even open non-enclosed printers without heated cabinets. PETG-CF is actually pretty strong and resilient… at least go that route.

PET, PA, PA12, PA612 are more engineer grade materials. A bit more expensive, but if holding a thousand dollar scope… They can be 2-4x stronger but really require a heated chamber, higher temps, special nozzles sometimes, just more to setup, but once you get it figured out or have the equipment, they are good final print type materials if quality is a concern. CF is also available in most of those.

Worth getting a roll of a few of these materials, print some and see. Create small parts and experiment with bending them, putting screws in them, tapping them, breaking them, etc… Biggest difference is if your equipment/printer will handle them. enclosures, filament driers are almost all necessary for the better materials to turn out good… in my experience.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I have printed things out of PLA, my rig doesn't get hot usually. If that's a concern then PETG should be OK unless it gets very hot. I'm with the previous post, I would not print the main plate out of anything except engineering materials, I use aluminium dovetails since failure of that foundation could mean loss/damage of everything.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

PLA is very weak in temp changes. When it's hot it becomes very soft. When it is cold it becomes brittle.

PET-G is one step up in terms of mechanical strength and it's a bit more resistant to both low and high temperatures, but it's quite flexible so I'd say it's not great for these uses where you want things to not bend.

The downside of stronger filaments is that they need an enclosure for printing. If you have one, go with either ABS or (even better) ASA. Be careful though, they emit toxic fumes during printing, so apart from enclosure for temperature you also need it ventilated to outside or through a very good filter.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Josh Jones:

It can really vary material wise what you need expectation wise and what hardware you have as well.

PLA, PETG or PETG-CF are some the lower end material in terms of strength but work fine depending on what you are needing. PLA though can be really really weak, especially in temp changes and if sun hits it. Again, depends on many variables like thickness of print, surface area, etc... but I would probably use it for prototyping and that's it, move on to better materials for astro gear. Nice thing about some of these materials is most printers will print them fine, even open non-enclosed printers without heated cabinets. PETG-CF is actually pretty strong and resilient... at least go that route.

PET, PA, PA12, PA612 are more engineer grade materials. A bit more expensive, but if holding a thousand dollar scope... They can be 2-4x stronger but really require a heated chamber, higher temps, special nozzles sometimes, just more to setup, but once you get it figured out or have the equipment, they are good final print type materials if quality is a concern. CF is also available in most of those.

Worth getting a roll of a few of these materials, print some and see. Create small parts and experiment with bending them, putting screws in them, tapping them, breaking them, etc... Biggest difference is if your equipment/printer will handle them. enclosures, filament driers are almost all necessary for the better materials to turn out good... in my experience. So I have a bambu lab p1s. It's enclosed. I do not have a dryer though. I just have an AMS ( I know thats not the same lol). I would like to print the parts with CF filament I just dont have any experience with it, but I guess theres no time like the present lol. thank you.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

So with an AMS, run PETG--CF, that works good in there, and I use the AMS all the time for that material in there. Thats good improvement. Good guide here showing strengths, weaknesses, and common setup items: https://bambulab.com/en/filament-guideMy go to for good quality stuff is a PA612-CF... I know some who go with PET-CF, others who go ASA... so it all depends, but they can be waaaay stronger. Also, keep in mind how you print is critical. Take a losmandy rail... printing it vertical or horizontal matters. For example if you print a silencer for a gun, it will come apart easily if you print it vertically since it relies on bonding strenghts, but print it horizontally (though not ideal for a cylinder), it will be much stronger strength wise. Personally, I'd use an aluminum rail, but I wouldn't hesitate for a scope ring setup using some good material... just not PLA.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

IMO milled carbon fibre is a bit of a gimmick. There's a reason Voron design advises against exotic materials like cf-nylon for building printers – they suffer from heat creep.

I use ASA or black ABS for scope parts and they work great – both UV resistant, shock proof, not too brittle and reasonably stable.

With an enclosed printer ASA and ABS are easy to print (PLA is not cheaper and harder to print as it needs more cooling). Black ABS is usually good enough (the black makes it UV stable), it is cheap, simple to print and much better than any PLA.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

John Wells:

IMO milled carbon fibre is a bit of a gimmick. There's a reason Voron design advises against exotic materials like cf-nylon for building printers -- they suffer from heat creep.

I use ASA or black ABS for scope parts and they work great -- both UV resistant, shock proof, not too brittle and reasonably stable.

With an enclosed printer ASA and ABS are easy to print (PLA is not cheaper and harder to print as it needs more cooling). Black ABS is usually good enough (the black makes it UV stable), it is cheap, simple to print and much better than any PLA. I agree ABS is nice for being UV resistant and not to brittle and cheap, but so are other materials, and it's not in the same territory for strength when it comes to the harder polycarbonates and nylons. You can feel the difference when you go to break a part with those materials where ABS and PETG and PLA all break down quickly and easily. If you start to print quality parts for things that matter with impact and strength, those materials are 2-3x the strength. A lot has to do with what infill and wall setup you use, but I wouldn't use ABS in critical things. Great for non-critical in my opinion.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

Josh Jones:

So with an AMS, run PETG--CF, that works good in there, and I use the AMS all the time for that material in there. Thats good improvement.

Good guide here showing strengths, weaknesses, and common setup items: https://bambulab.com/en/filament-guide

My go to for good quality stuff is a PA612-CF... I know some who go with PET-CF, others who go ASA... so it all depends, but they can be waaaay stronger.

Also, keep in mind how you print is critical. Take a losmandy rail... printing it vertical or horizontal matters. For example if you print a silencer for a gun, it will come apart easily if you print it vertically since it relies on bonding strenghts, but print it horizontally (though not ideal for a cylinder), it will be much stronger strength wise.

Personally, I'd use an aluminum rail, but I wouldn't hesitate for a scope ring setup using some good material... just not PLA. I too would prefer to use an aluminum rail, In fact I am using one now. But because of that I am just a bit over the payload capacity of the the star adventurer GTI. I was hoping to print a rail to reduce the overall weight of the set up.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

PC-CF is very good, but you need to be careful when you are using it for parts as it will hold quite well and is extremely strong but when you exceed its tolerances it will break catastrophically (by design). Usually PC-CF only requires a hardened steel nozzle and higher nozzle and bed temps. The X1 Carbon for example can be fitted from the factory to print PC-CF no problem.

Source good PC-CF filament as well. We only use Prusa PC-CF and have yet to find another that comes close to the quality.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.

I have a simple Ender 3 Neo upgraded with a direct extruder. (highly recommended). I have printed many things for my astro gear: electronic focuser (electronics box, frame for stepper motor and pinions for the belt), case for my power box, holder for my mini PC, holder for my guidescope, cable lamps, frame for my diy flat panel and many Bathinov masks .

I print in PETG, TPU, but mostly I simply choose PLA or PLA-CF. because it prints easier. Outdoors PLA-CF seems to hold up pretty well. in moist or summer conditions.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Copy the URL below to share a direct link to this post.

This post cannot be edited using the classic forums editor.

To edit this post, please enable the "New forums experience" in your settings.